Putting thorium through its paces: Thor at the Halden reactor in Norway

A group of evangelists are singing the praises of a new type of nuclear fuel. They say that with the correct technology it can generate safer, cheaper and cleaner nuclear power than uranium. For those who have not heard the tune, it’s about thorium – a naturally occurring element found in rock and soil (see box, facing page). Using thorium to generate nuclear power has captivated more than one generation of engineers. Research into the thorium fuel cycle began more than 60 years ago, but so far the technology has yet to find itself in the spotlight.

Over the years, nuclear scientists have built demonstrators of new reactor designs that could use the element. Thorium-based fuels could generate power in heavy-water reactors, high-temperature gas-cooled reactors, boiling and pressurised light-water reactors, and fast neutron reactors.

But never has the level of investment in thorium come close to that pumped into the uranium fuel cycle, which at the birth of the nuclear industry was favoured because of the military applications of its by-product, plutonium.

Things might be changing. One of those thorium concepts from the early years has seen a resurgence of interest. An international nuclear futures task force picked it from a pile of 100 concepts as one of six that it believes represent the future of nuclear energy. The molten salt reactor, as it is known, is listed alongside gas- and sodium-cooled fast reactors as clean, safe and cost-effective technology for the fourth generation of nuclear power.

Work on molten salt reactors began in the 1940s at the Oak Ridge National Laboratory in Tennessee as a project to develop an alternative to jet engines for bomber aircraft. By the mid-1950s, scientists had turned their attention to using the reactors in nuclear power stations and had built a test reactor that ran from 1965 to 1969, generating 8MWth. But in the 1970s, the US Atomic Energy Commission shut down the programme. Although some work continued at Oak Ridge in the 1980s, funding dried up and few advances were made.

Decades passed until, in 2000, an engineer working at Nasa’s Marshall Space Flight Center in Alabama came across the technology in a book. He was looking for a way to power spacecraft and communities on the moon, and thought a thorium molten salt reactor could fit the bill. The engineer, Kirk Sorensen, went on to found the company Flibe Energy, which is working to bring a molten salt reactor design to commercial fruition (see bottom of the article).

Flibe’s version of the molten salt reactor is known as a liquid-fluoride thorium reactor (LFTR). It is fuelled by uranium-233 bred from thorium, and the fuel is dissolved in a mixture of lithium fluoride and beryllium fluoride salts that is heated to more than 400°C. To start it up, the whole set-up needs highly enriched uranium, uranium-233 or plutonium. LFTRs operated on uranium-233 produce almost no plutonium, says Sorensen.

The molten salt reactor concept needs a lot more work before it can be licensed, according to Bob Cywinski, professor of physics at the University of Huddersfield. Yet it has advantages. “People say it can’t melt down because it’s already molten,” he adds.

The molten salt can act as a temperature regulator, he says. As the mixture gets hotter the liquid expands, which pushes the fissile components further apart, causing a drop in reactivity. Once the reactivity drops, the temperature falls, so the molten salt starts to shrink again.

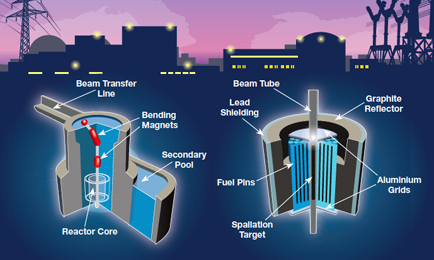

But meanwhile Cywinski is working on a different type of reactor that he thinks could one day realise the thorium dream. It uses a particle accelerator to help generate the neutron that thorium must acquire to become fissile.

The accelerator drives a high-energy proton beam into a lead target embedded in the centre of a nuclear reactor filled with thorium. As the protons slam into the lead, neutrons are chipped off and convert thorium in the reactor to uranium-233. Depending on the target material, each proton can chip off about 30 neutrons, and it is these same neutrons that trigger fission in the uranium-233. “You don’t need a chain reaction,” says Cywinski.

Without a nuclear chain reaction to control, operators could effectively switch off the reactor by flicking the switch that shuts off the proton accelerator. Shutdown would not be instant – fission would continue and decay heat from the radioactive products produced in the process would remain, but non-invasive control of the reactor would be possible.

Not all neutrons are created equal. As a group, those that are chipped off lead by an accelerated proton beam have a larger proportion at high energies compared with the neutrons derived from fission. These high-energy neutrons can burn up the most radioactive products of fission languishing in the reactor, resulting in less nasty waste than that produced in a conventional reactor.

The idea for this accelerator-driven subcritical reactor (ADSR), as it is known, has been sitting on nuclear physicists’ drawing-boards for the past 20 years. The reactor has some high-profile fans, including Nobel Prize winner Carlo Rubbia, ex-director general of Cern. International firm Jacobs Engineering is developing its own version of the technology.

Advocates of the technology say that the output of the reactor can be adjusted according to demand, by ramping up or down the power of the accelerator. But as with Sorensen’s LFTR, accelerator-driven reactors need work before they can be commercialised. “There is a real advantage to this technology, but whether it would ever be used routinely to generate power is an open question,” says Cywinski.

Energy companies are reluctant to invest in these next-generation reactors, even though the technology promises power using an abundant fuel without risking nuclear meltdown while producing less radioactive waste. Kevin Hesketh, a senior research fellow at the National Nuclear Laboratory (NNL), says: “There needs to be a strong differentiator in favour of thorium fuel cycles for utilities to buy into it – and that isn’t there.”

For a utility company, the cost of fuel is only a small proportion of the cost of running a nuclear reactor. So a small saving on fuel costs is not enough to compensate for the risk of using a new fuel.

Utility companies are not the only ones yet to be convinced by thorium. Dr Steve Ashley, research associate at the Engineering Design Centre at the University of Cambridge, believes that thorium evangelists can overstate and cherrypick certain arguments in favour of the fuel.

One of the often touted benefits of the thorium fuel cycle is that it is less easy to use it to create nuclear weapons than uranium. But this is something that Ashley and his colleagues refute. “If you have uranium-233 separated out, then it could be weaponisable,” he says.e been made using plutonium. But back in 1955, scientists conducted two tests using uranium-233. In fact, the International Atomic Energy Agency says the amount of uranium-233 needed to make a nuclear device is the same as that of plutonium: 8kg.

Flibe Energy says that the LFTR has lower capital costs than a conventional reactor because it does not require pressure vessels or containment domes and can be mass-produced. But Ashley contends that it appears cheaper because it has never been built.

Made to measure: Thor will collect a range of data

Made to measure: Thor will collect a range of data

Ever since the disasters at Three Mile Island and Chernobyl, Ashley says the industry has been upfront about the risks and benefits of nuclear power. “My worry with thorium is that not looking at the whole thing openly is detrimental, because the regulators will look at the complete picture.”

Putting LFTRs and ADSRs up for scrutiny by the regulators is still a long way off. Hesketh sees no realistic prospect of new-generation reactors in the near future. Up to the 2050 horizon, the world’s fleet will be dominated by light-water reactors and Candus (heavy-water reactors), he says. “If you were to adopt a thorium fuel cycle, you would have to do it in the existing fleet of reactors,” he adds.

Supplementing uranium with thorium in existing reactors is not straightforward. Hesketh claims that any benefits of using thorium in this way could “melt away” once a system is engineered.

But Thor Energy, a nuclear fuel technology company in Norway, is hoping to change all that. It is developing thorium-based fuels for use in light-water reactors, and its partners include Westinghouse and the NNL. In April, its engineers loaded a test rig containing rods made of three types of thorium-based oxide fuel pellets into the Halden reactor at Norway’s Institute of Energy Technology.

The aim is to irradiate the new fuels for a total of 60MW days – the equivalent of five years of use in a commercial reactor. The Halden reactor is fitted with equipment that allows engineers to measure temperature, thermal conductivity, material stability and neutronic behaviour while the experimental fuel rods are irradiated. Five years gives Thor time to collect all the data needed to apply for a licence to load the fuel into a commercial reactor. The first results came in within hours of starting the experiment.

So far, the results have proved “boring” says Thor’s chief executive, Øystein Asphjell. But one of the mixtures – conventional uranium pellets containing a little thorium – is conducting heat slightly better than expected.

During fission, enormous amounts of energy are produced inside each of the fuel pellets, which measure just 9.6mm in diameter. Across the tiny surface from the centre of the pellet to the edge, temperature gradients can span 1,000°C. It is this heat energy that boils the water surrounding the reactor core to produce steam that pushes a turbine to generate power.

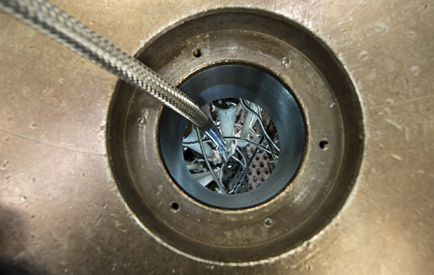

Five-year foray: Thor’s rig entering the test reactor

Five-year foray: Thor’s rig entering the test reactor

“Getting this energy out of the pellet faster means that at any time you will have a lower contained heat in the fuel and the reactor core,” says Asphjell. This means fuel will run cooler than it does with uranium, and the pellets will be under less strain and less liable to crack – boosting safety margins. Operation margins will increase, he adds.

Thorium’s first foray into the mainstream nuclear fuel market may come from supplementing uranium. But other uses of thorium are being considered. Thor is testing pellets made of thorium and plutonium at Halden. This approach could prove interesting for the UK, which has stockpiled 112 tonnes of plutonium from reprocessing spent nuclear fuel at Sellafield since the 1950s with the hope of using it as a nuclear fuel in the future. The cost of keeping it safe runs to £80 million a year.

Thorium could provide one option to generate power from this plutonium, in existing and new-build reactors. Research has suggested that mixing thorium and plutonium as a fuel can destroy many of the radioactive fission products that make plutonium waste so nasty.

But before any of this can happen, Thor’s second round of tests in commercial reactors must be completed. Discussions are under way as to where those tests could take place. A “handful” of markets are of interest, says Asphjell. Although he could not disclose whether the UK is on the shortlist, he adds that it has factors that make it an attractive location.

Using thorium in this way could bring benefits, but is still 10-20 years away from becoming a reality, says NNL’s Hesketh.

In the meantime, the government’s preferred route is to recycle the plutonium into a uranium mixed-oxide fuel, a process that is already under way in Europe. France manufactures 190 tonnes of this fuel every year at Areva’s Melox plant in the Gard region and burns it in 25 of the country’s reactors. Plutonium-uranium mixed-oxide fuel is also used in Germany and Belgium.

But reprocessing plutonium, even into fuel that can be used to generate power, does not come cheap. The question will remain as to whether it is more cost-effective to stow it away underground.

With so many of thorium’s benefits still up for debate, there is a chance it could find itself on the drawing board for another 50 years – but not if the evangelists have anything to say about it.

What is thorium?

Thorium is a slightly radioactive metal found in rocks and soils. It is three times more abundant than uranium. The element has a very long half-life, and is not capable of undergoing nuclear fission alone.

If irradiated, naturally occurring thorium-232 gains a neutron and converts to an isotope, thorium-233. This is unstable and decays into protactinium-233, and then into uranium-233.

This uranium-233 readily fissions, producing heat and releasing neutrons that trigger a nuclear chain reaction.

How does a molten salt reactor work?

Molten salt reactors have a core of molten salt uranium-233 that is surrounded by a blanket of thorium salt. As the material in the core is fissile, it undergoes fission to produce neutrons that convert thorium in the blanket to protactinium-233. The protactinium-233 is bled out of the blanket and left to decay to uranium-233, which is fed back into the core. Flibe Energy is developing a liquid fluoride thorium reactor based on the principles of a molten salt reactor. The heat generated from fission is transferred through heat exchangers to a clean coolant salt loop, which transfers the heat to the fluid of a gas turbine to generate power. The fuel salt, blanket salt and clean coolant salt circuits all run at near atmospheric pressure. The company says this improves safety compared with conventional water-cooled reactors that run under pressure, leaving them liable to explosion.

An accelerator-driven subcritical reactor

India fast-tracks thorium cycle

India fast-tracks thorium cycle

For many years India harboured a nuclear weapons programme that kept it outside the Nuclear Non-Proliferation Treaty. This meant the country was banned from trading nuclear fuel or plant materials. India has limited uranium of its own, and its engineers have developed the country’s civil nuclear power programme largely without fuel or technological knowledge from elsewhere.

But the country is home to the world’s largest thorium reserves, and a long-term goal of its nuclear programme is to develop an advanced, heavy-water, thorium cycle. The cycle has three stages, the first of which uses pressurised heavy-water reactors fuelled by natural uranium, and light-water reactors to produce plutonium. Next, fast neutron reactors burn the plutonium to breed uranium-233 from thorium. Finally, advanced heavy-water reactors burn this uranium-233, along with plutonium and thorium. About two-thirds of the power produced at this stage comes from thorium.

Although international authorities have now lifted some restrictions on trade, India’s thorium programme continues. The first commercial fast neutron reactor at Kalpakkam, Tamil Nadu, is now almost complete and set for switch-on in 2014. The reactor has a 500MW (e) capacity and fulfils the second stage in the three-stage programme. A further six fast neutron 500MW (e) reactors are planned. The advanced heavy-water reactors needed for the third stage of the programme will be built in 2017, the plans suggest.

Kevin Hesketh, senior research fellow at the UK’s National Nuclear Laboratory, says the fast neutron reactors and advanced heavy-water reactors being developed in India are unique. “It’s a prestige project,” he says. “It probably wouldn’t survive the kind of scrutiny we would give it here for economics.”