You might not necessarily have thought that the nouveau riche of China had much concern with the Isle of Man – although the tourist board could no doubt make a convincing case for them doing so. Nor would you necessarily have thought that a tiny manufacturer on the island would be engaged in exporting luxury timepieces to the Far East.

Indeed, industry and the island might seem, to the uninitiated, incompatible. The place is, after all, best known as a summer retreat for those residing in North West England, the setting for the TT motorcycle race, and a haven for cats with curious tails.

But manufacturing tales are also to be found, if you know where to look. In cottages with industries, for example, one of which houses Roger Smith’s watchmaking business. The state-of-the-art five-axis milling machine in Smith’s workshop is an indicator that he is prepared to use modern technology but the beautifully maintained lathes and Swiss watchmaking equipment from previous centuries are more in tune with the spirit of the business.

Much of that equipment once belonged to Smith’s mentor, Dr George Daniels, the finest English watchmaker of his generation. Daniels painstakingly taught Smith the art of horology as it was practised in the days when making a single pocket watch by hand would involve the watchmaker and 34 separate trades.

Daniels’ tutelage had a profound effect on Smith, who began to dream of creating his own watches built to the standards of English watchmaking in the 18th and 19th centuries, before mass production.

Smith says: “I’ve always been keen on the manufacturing of watches rather than just repairing them, and working with George opened up a whole new world.

“It just seems to draw you in. But there was a lot of naivety. I thought it would be simpler than it was, and in a really short space of time I’d be making great watches. Twenty years later, we got to the level of quality and standard that I desired.”

“Quality” is perhaps an overused word in the engineering industry but for Smith – and customers paying upwards of £80,000 a watch – it means everything. He has mastered a set of technical disciplines and manufacturing, design and finishing processes derived from the classic English watchmaking techniques, and it is this, he says, that makes his watches unique.

Components can be made from a range of materials including gold, steel and bronze to tolerances of 2-3 microns. Each component is finished and polished entirely by hand. In fact, Smith estimates that 80-85% of the work that goes into one of his watches is by hand. Lettering is engraved by hand, and the best paints and lacquers are used with the aim of creating a “thing of beauty,” says Smith.

Build time for a single watch – Smith has a team of four – is six to eight months, and the customer base includes not just China, but also the US and the UK.

If the venture seems crazy, Smith says it is born out of a desire to revive skills long-since lost. “It’s just a different approach,” he says. “These watches are made to order and it’s all about the handiwork – the skill of the craftsman sitting there.”

The supportive environment for business on the Isle of Man has been critical to making the workshop a reality, he adds. He has been able to take on and train locals. And he has taken advantage of the grants the government makes available to help buy equipment. “Without that assistance we wouldn’t have been able to do what I wanted to do – in fact, we wouldn’t have survived in England.”

The business could grow if Smith took on another watchmaker but he says he has no desire to see it explode. “I always say, if you ever hear that we’re making 50 or 100 watches a year, the quality will have had to have lessened – and I’m simply not prepared to do that.”

Across the island near the capital, Douglas, Sakkie Meeuwsen has overseen the development of a biomedical business that is taking on some of the world’s biggest pharmaceutical companies. Meeuwsen is managing director of Bodystat, which is involved in body composition analysis using bioelectrical-impedance. This provides a safe and reliable means of determining body composition – fat, muscle mass and water.

Many Bupa hospitals use equipment developed by Bodystat, as does the NHS and other healthcare services around the world. Appropriately enough for such an ambitious venture, Meeuwsen has recently completed the construction of his own headquarters on a plot of land on a hill at Ballakaap. But the firm has been in business for 22 years.

At the basic end of the scale, Bodystat equipment is used for personal training and fitness assessment, right through to weight management. At the higher end, where the firm has developed a touchscreen device that it believes is among the most advanced of its type, the equipment is used as an aid to haemodialysis for kidney patients, for nutritional support, and in the treatment of lymphoedema, a chronic condition that causes swelling in the body’s tissue, leading to pain and a loss of mobility.

Meeuwsen says: “We can also look at fluid shifts in the lungs and extra-cellular pooling-up of water following operations, or while the patient is lying in the intensive care unit. There’s quite a range of medical applications and a number of others under research, so our challenge is to take that research and translate it into sales.”

Meeuwsen, a chartered accountant by background, ran a leather tannery in South Africa before emigrating with his family to the Isle of Man in 1990 and launching Bodystat. Much of the technology in his firm’s devices was originally developed in the US but had to be re-engineered for the British and other markets. Meeuwsen has never employed engineers full-time but fortuitously found another company on the island that was able to develop the electronics and software for Bodystat devices. Nowadays this work is carried out in Leeds, where Meeuwsen has a distributor, but the island continues to provide opportunities.

He says: “I found out about this technology that originated from the US and it just made sense, although the Americans had it in big computer boxes and I thought: ‘There has to be an easier way’.

“We just redeveloped it all ourselves. Now we’re in talks with another company on the island about correlating their technology, which can measure prediction of outcome and state of disease, with ours. Bodystat equipment has already been used for prediction of outcome in surgical patients: there could be leakage or a fluid that we’re able to detect before it becomes clinically obvious.”

Now Meeuwsen hopes to work with his counterparts on the island to develop new systems that can participate in clinical trials. “We never knew they were on the island but the Department of Economic Development got us together. So we’re going to collaborate with them and incorporate some of our technology into theirs,” he says.

Even at the less advanced end of the scale, the firm’s systems can pick up on things that might otherwise be missed by a GP, he says. “Our prime case is severely obese people. They go to the doctor complaining of being unwell and might be told they need to lose weight – exercise and eat correctly. But without this technology it’s possible to miss that something inside the body is going wrong: it could be the early onset of cancer for example. Obesity can mask this disease which is developing with obvious consequences for the NHS. We’re trying to give an early warning indicator.”

Pharmaceutical companies are becoming increasingly interested in bioelectrical-impedance technology, and some have ploughed millions into the development of the systems. Meeuwsen is confident that Bodystat can compete, however. “There are big organisations with no limit to their budgets and we have to compete with them,” he says. “But in fact we are already selling into pharma companies: doing clinical trials of drugs, they need to know if they are going to increase lean body mass or reduce or increase fat.

“They can use our technology to add to their bag of tricks, to help prove the safety and effectiveness of new drugs. So that’s good business for us.”

Meeuwsen is 67 now but when he retires the business will be run by his daughters. Part of the attraction is the charm of the island itself, he says. “My daughters love the island; they can’t get back quickly enough. There’s a lot to be said for quality of life – and the quality of life here is tremendous.”

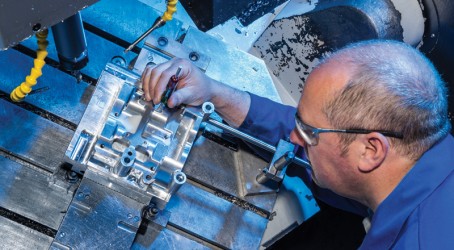

It is a similar love story for Steve Riding, the Liverpudlian sales director at precision engineering firm Kiartys. With a small team, Kiartys specialises in making low-volume pre-production components for several sectors. The business has strong links to the Isle of Man’s aerospace industry. The company – Kiartys means “true” or “precise” in the Manx language – makes parts destined for the Trent 1000 and XWB aeroengine programmes.

“Most of our work is with local companies,” explains Riding. “We’ve developed as a result of being part of the Isle of Man aerospace cluster, which has helped us attain important quality standards.

“We find the cluster is good generally because it gives us access to the bigger players on the island such as Ronaldsway, Swagelok and GE. It also helps us to stay in touch with smaller subcontractors over here.” Kiartys enjoys regular meetings with the Department of Economic Development.

Riding says he would love to take on an apprentice, but his small team doesn’t have the time to train one. “It’s a hands to the pump sort of thing: get the work in, get it out – and then find other work. All of which is highly skilled.”

Kiartys has benefited from the introduction of new five-axis machinery under the government’s favourable economic regime. The equipment allows the firm to produce bigger batches, but the focus remains largely on pre-production parts and prototypes.

There has been a slight decline in the market this year compared to 2011, says Riding. “We’ve seen more of an increase in aerospace than our commercial work. Overall, however, I’m not losing sleep over it. We’ve had other, bigger worries in the past. And this industry can be perverse: it can go quiet and then work starts coming out of nowhere.”

From watchmakers to biomedical companies, the Isle of Man holds many of its own surprises for the visitor.