Now, Canadian company HydroGraph hopes some upcoming products could realise graphene’s true potential in a wide range of applications, from lightweight aerospace and marine components to stronger construction materials.

Last week (4 September), the Vancouver firm submitted two patent applications for ‘graphene-coated hollow glass microspheres’ (HGMS), adding the 2D carbon material to tiny glass bubbles.

“What we're doing here is taking an industrial commodity additive material, and converting it to much higher value items by basically putting our fractal graphene and reactive graphene onto them,” said chief science officer Ranjith Divigalpitiya to Professional Engineering.

Fractal graphene, also known as ‘pristine’ graphene, is so called because the particles aggregate in a fractal structure, like tree branches. “HydroGraph’s pristine graphene, or fractal graphene, is very different from what is being sold as graphene in the world right now,” said the company’s graphene materials expert.

The main method of graphene production is ‘top down’, peeling layers off graphite one-by-one. This requires a lot of energy, however, and can contain impurities from the graphite. Bottom-up, another popular production method, builds graphene atom-by-atom using chemical vapour deposition. HydroGraph takes a different, explosive approach.

“We take acetylene and oxygen, mix in a chamber, and – using a small electrical spark – you explode the mixture. So there's no catalyst, no chemistry going on per se,” said Divigalpitiya. “It's a super clean process, it's very deterministic, very reproducible from detonation to detonation.”

The resulting graphene particles are “truly nano-size”, only a couple of nanometres thick. Although Divigalpitiya said the company is approaching “ideal” graphene, the material still has a few layers of carbon atoms.

The glass shells are typically less than 100 micrometres wide, so the nanometre scale graphene maintains their low density and weight. Applied to the spheres, the coatings convert the white, insulating glass bubbles into electrically and thermally conducting free-flowing powder.

The first of last week’s patent applications covers HGMS coated with pristine graphene. The second focuses on HGMS coated with reactive graphene, which has added carboxylate groups.

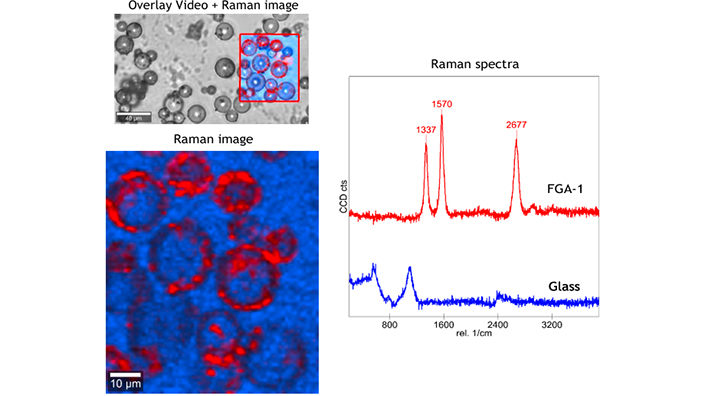

Chemical imaging showing the fractal graphene coating (FGA-1, red) on the surface of the glass microspheres (blue) using Raman spectroscopy

Some companies have been wary of using graphene because of the care needed during handling, said Divigalpitiya. By adding their graphene to the glass balls, HydroGraph hopes to provide a ‘drop-in’ solution that could reduce weight or increase strength in numerous applications.

Glass bubbles are already added to resins and plastic materials, replacing some of the main material with air and a tiny bit of glass. Doing so can cut the weight by as much as 60%, said Divigalpitiya. Including graphene as well creates a “synergy”, he said.

The new materials’ electrical conductivity could make them well-suited for lightweight electromagnetic interference (EMI) shields, the company said, as well as in plastic parts for industries such as automotive, marine and aerospace. By cutting the weight of components, vehicles could use less energy or have longer range.

Other applications might take advantage of the spheres’ thermal conductivity, or their ability to act as lubricants in flow.

The bubbles could also be used in the production of lightweight, high-strength concrete. A study by the environmental and engineering department at Arizona State University found that “tiny quantities” of fractal graphene could improve the compressive strength of concrete, reducing pore size to prevent water ingress and increase its durability.

“Our hope is if we use coated glass bubbles in concrete for specialty applications, we can have a ‘super concrete’, a very high-value item that will last longer, [with] much higher strength and less corrosion,” said Divigalpitiya.

The bubbles can be thought of as a support material for graphene nanostructures, the company added, which could also make them suitable for filtering and absorbing contaminants.

“Our new patent applications demonstrate our dedication to pushing the boundaries of what’s possible with graphene to deliver cutting-edge, customised solutions to meet the evolving needs of our partners,” said Kjirstin Breure, president and interim CEO. “This innovation opens new possibilities for lightweight, high-strength materials.”

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.