COVID-19 Manual Section 9: Manufacturing Industries, Living with COVID in Manufacturing

Introduction

This guidance was compiled on the 6th May 2021 and is based on the latest published UK and devolved government guidelines at this time (see further information at the end of this section). It aims to provide a succinct summary of the key considerations, supported by practical recommendation and signposting to additional sources of information.

Every organisation needs to take appropriate actions which reflects the size and nature of the business and also how it operates. It is critically important that the effectiveness of any control measures are regularly reviewed. This guidance does not supersede any legal obligations relating to health and safety, employment or equalities, and it is important that as a business or an employer you continue to comply with your existing obligations, including those relating to individuals with protected characteristics.

To help decide which actions to take an appropriate COVID-19 Risk Assessment should be undertaken.

Covid-19 Risk Assessment

A comprehensive risk assessment should be undertaken in considering the facilities, operations and people across the entire business. Facilities should include non-production areas where people would normally congregate, including canteens, corridors and changing rooms. This should consider reasonable adjustments needed for staff and visitors with disabilities. Where appropriate, individual occupational risk assessment should be undertaken for individual employees, particularly those who are deemed vulnerable to Covid-19 or have close contact with a vulnerable person. The risk assessment should be undertaken in consultation with employees, employee representatives or trade unions.

Recommendations for dealing with Covid-19

Recommendations in terms of the changes to facility and operating practice, as well as potential support for staff are detailed below. Implementation should be based on the outcome of the Covid-19 Risk Assessment.

Facility Modifications;

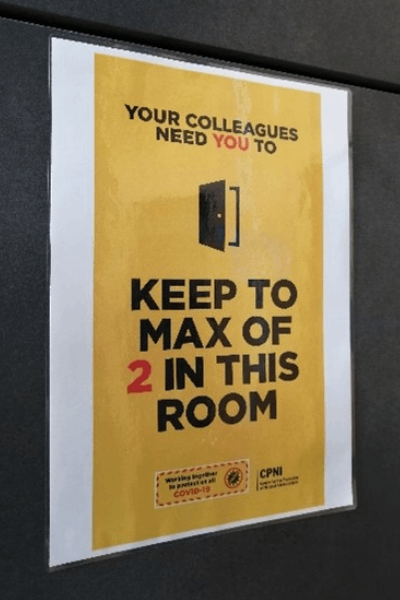

Clear signage – in addition to reminding staff about use of face coverings, maintaining social distancing and regular hand washing, signage should be used to help staff and visitors understand changes made to the use of the facility due to Covid-19. Signage includes use of floor marking to help staff and visitors comply with the prevailing social distancing guidelines

Instructions for visitors (source: MTC)

Reminder to maintain social distancing (source: MTC)

Cleaning more often – cleaning of contact surfaces, particularly door handles, hand rails etc. needs to be appropriately scheduled (ideally to coincide with shift/team changeover etc) and regularly checked. If you are cleaning after a known or suspected case of COVID-19 then you refer to the guidance on cleaning in non-healthcare settings (https://www.gov.uk/government/publications/covid-19-decontamination-in-non-healthcare-settings/covid-19-decontamination-in-non-healthcare-settings).

Creating space – measures include reducing the number of people, avoiding face-to-face working (back-to-back and side-to-side is regarded as being safer) and where appropriate using barriers between workstations or to control the flow of people in corridors.

Signage to control room occupancy using template from Centre for the Protection of National Infrastructure (source: MTC)

Hand washing – if needed install sanitizer dispensing points and, where possible, additional hand washing facilities.

Clear marking of sanitizer dispensers (Source: MTC)

Improved ventilation – supplying fresh air to enclosed spaces where people are present using natural ventilation through windows and doors as, well as forced ventilation using fans. It may be possible to add sterilisation of air into the ventilation system.

(further advice can be found at https://www.hse.gov.uk/coronavirus/index.htm)

Reduce noise - Keep background noise (such as music) to a minimum to improve communication, without the need for shouting or close proximity communication.

Operational Changes;

Home working - Anyone who can work from home should do so where appropriate but please remember that a Display Screen Equipment (DSE) assessment should be undertaken and appropriate equipment provided to ensure a safe home working environment.

Forming work “bubbles” - Structure staff to work in teams (work bubbles) which do not mix thus reducing the number of contacts and the risk of transmitting Covid-19, as well as enabling more effective containment of any outbreak. Where possible the start-finish and break times for different bubbles should be staggered to reduce the risk of mixing.

Keeping Covid-19 at bay - Staff and visitors should be reminded that if they or someone they are living with are displaying Covid-19 symptoms or have been contacted through the NHS Test & Trace system they should be isolating (in accordance with the prevailing guidelines). Companies may consider asking staff and visitors to sign a declaration confirming their health status and /or introducing temperature testing before entry is allowed to a site. All organisations should support the NHS Test & Trace activity by keeping a record of staff and contractors for 21 days (see https://www.gov.uk/guidance/maintaining-records-of-staff-customers-and-visitors-to-support-nhs-test-and-trace).

Wearing Personal Protective Equipment (PPE) – face coverings should be used in any indoor space or where required by law, unless exemptions apply (see https://www.gov.uk/government/publications/face-coverings-when-to-wear-one-and-how-to-make-your-own/face-coverings-when-to-wear-one-and-how-to-make-your-own).

Travel and off-site visits - Offsite visits should be managed through the risk assessment process. There should be a clear and compelling need for the visit and it should only proceed where appropriate planning and risk mitigation measures have been put in place (this may include assessing the hosts Covid-19 control measures). Travel to and from work should consider the level of risk. Government guidance recommends walking or cycling where possible. Appropriate precautions should be taken when using public transport, including the use face coverings and social distancing (if possible). Where possible only car share with people within your work bubble.

Control of goods – the transfer of goods into and out of a site provides an opportunity for Covid-19 transmission. Improved levels of control, planning and communication should be introduced where possible to reduce the risk.

Supporting Staff;

In these challenging times it is critically important that organisations provide support for staff.

Effective communication – keeping staff informed not only ensures that they are aware of the latest guidelines but also reduces the feeling of isolation, particularly for those who are vulnerable and/or working from home. Take steps to ensure that disabled people are informed about new procedures, and are able to access facilities, i.e. handwashing facilities at wheelchair height, verbal direction for those unable to see floor markings or signage, etc.

Conduct Training – training may be required where significant changes to operating procedures are being introduced.

Consider mental health – introduce or strengthen support mechanisms to promote positive mental health and wellbeing in the workforce, particularly employees who may be anxious about the risk to their health and livelihood from Covid-19.

Planning & Investing for the future

Covid-19 has placed significant strain on many businesses, including those in the manufacturing sector. Companies have had to deal with dramatic changes in demand for products and services, as well as coping with severe interruptions to the supply chain.

This experience has underlined the need for greater resilience within the manufacturing sector, not only to deal with the impact of pandemics but also other seismic disruption, such as climate change and new global trading arrangements.

Reassessing supply chain – the robustness of supply chains can be assessed using tools, such as value stream mapping. In many cases companies will need to consider if shortening supply chain, using local suppliers or in-house manufacturing, is a better approach.

Increase agility – companies need to be able to rapidly adjust production to cater for changes in demand and also take full advantage of new opportunities when they arise. This requires not only new manufacturing approaches but also significant organisation changes

Investing in technology – harnessing digital manufacturing will be essential for companies to offer competitive and sustainable products in the future. Robots and automation will also play an increasingly important role, not just in high volume assembly but in lower volume production and across a wider range of manufacturing processes. New manufacturing methods, such as Additive Manufacturing, which provide greater design and manufacturing flexibility should be investigated.

Robotic assembly operation (Source: MTC)

Sources of funding and support – UK companies can gain support to help develop and implement new manufacturing technology (for more information visit https://www.gov.uk/government/organisations/innovate-uk).

Further sources of information

https://www.gov.uk/guidance/working-safely-during-coronavirus-covid-19/factories-plants-and-warehouses

https://gov.wales/manufacturing-coronavirus-guidance-html

https://www.hseni.gov.uk/articles/covid-19-workplace-safety-guidance

https://www.hse.gov.uk/contact/

https://www.cpni.gov.uk/security-campaigns/covid-19-workplace-actions-0

https://hvm.catapult.org.uk/