Articles

In the early 1970s George Jeronimidis, working with Jim Gordon at Reading University, made models of wood with tubes of helically wound glass fibres, impregnated with resin.

The fibre winding was at 15º to the long axis of the tube; not only is this angle commonly found in wood cells, but George’s analysis showed that it’s the sweet spot in the trade-off between longitudinal stiffness and strength and the work of fracture. In tension the fibres in the tube wall tend to rotate in line with the strain until the resin between the fibres fails in shear. This allows the fibres to reorientate and the tube to extend with the fibres still supporting a load. This pseudoductility is remarkable since glass and epoxy (and cellulose and lignin in wood) are brittle.

The tubes buckle inwards and pull away from each other. In wood this increases the area of the fracture surface to at least 200 times the nominal section area. These mechanisms result in graceful and tough failure. A plate of George’s Wood in a drop-weight test had specific energy absorption five times greater than toughened steel. Like wood, you can join it with nails or screws and inject resin down the tubes to repair damage. A solid sheet of carbon-fibre-reinforced polymer shattered when a bullet was fired into it. George’s Wood held the bullet and had 85-90% residual strength. As body armour you can stab it with a knife – but you can’t pull the knife out for further thrusts. The tubes in George’s Wood can be made with any fibre or mixture of fibres and at different sizes, depending on the threat. The overall properties arise from structure, not from specific materials; the important factor is the angle between the fibres and the longitudinal voids – when the tube wall buckles or bends it needs somewhere to go; the voids are integral to the behaviour.

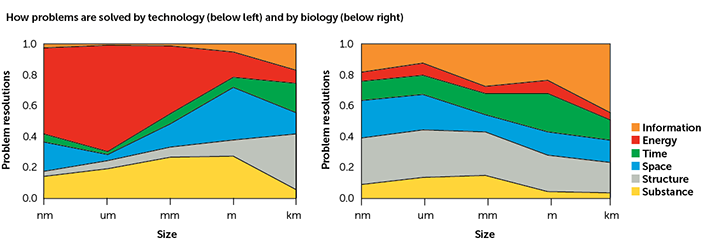

Structure, which requires assembly, is one of the roots of biology. The graphs below show this more generally. They were generated from several thousand data points from the internet and from research papers. They show the proportion of problems resolved by each of six parameters at different sizes. The data are imprecise. Even so the two graphs are very different.

In technology, energy rules, especially at the level of materials processing; heterogeneity (related to information) is destroyed to generate material that is more easily manipulated during manufacture. Raw material (‘substance’) is also important. By contrast, energy is hardly significant in biology, partly because all processing is done at ambient temperatures.

Structure presents many opportunities. George’s Wood is just one example. Mother of pearl is another; its structure can generate fireproof paper.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.