Articles

The electric motors whine at an increasingly high pitch as they struggle against gravity. The fixed-wing aircraft begins to rotate through 360 degrees across the ground as the vehicle’s dynamics struggle with the unusual force of three rotors trying to lift it vertically. For a moment it looks like the craft won’t get airborne. But then, with a last shriek of effort, the vehicle is hovering slightly unsteadily above the ground.

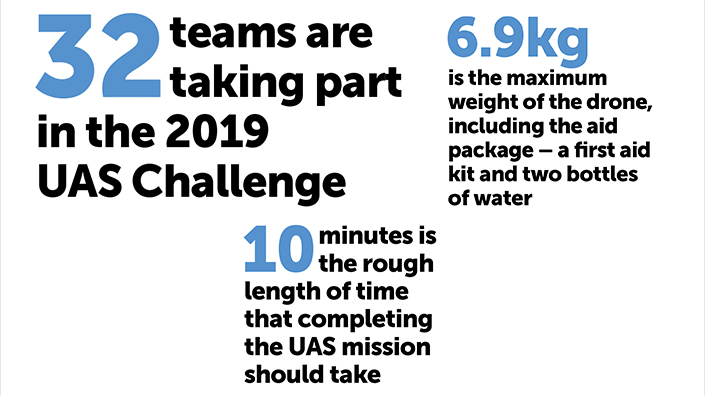

This is flight testing at the University of Southampton for the IMechE’s 2019 UAS Challenge, a competition in which students from around the world build and fly drones to complete various tests. This year’s mission is a mock humanitarian aid assignment in which the drones will undergo a series of challenges that simulate a disaster-relief scenario, such as speed, navigation, payload dropping, and accurate take-off and landing.

Bad vibrations

The competition poses several challenges, some of which are more suited to fixed-wing and others to rotary-powered aircraft. As ever, the greatest test will be to find the design that best covers all these bases. That is why the University of Southampton’s Team VOLTA has gone for a hybrid tricopter/fixed-wing aircraft that can take off using rotors before transitioning to an aerofoil for forward flight.

“The two things that are driving the design for me are just mass and simplicity,” says team leader Cameron Boyd. “We don’t want to reinvent the wheel, but for our design hopefully we can take off in one mode and go into a second mode.”

The hardest aspect will be the transition between the two modes of flight. Team VOLTA will use a tilt mechanism that will flip the rotors 90 degrees between vertical take-off and forward flight.

“The most difficult part is getting rid of vibration,” says Boyd. “When you’ve got that tilting aspect to it, you’ve got moving parts, you’ve got tolerances, so that’s probably the hardest part.”

Time pressures

The team hasn’t yet flight tested the transition, or indeed the fixed-wing aspect, but hopes to do so within the next two weeks. It’s all part of a busy schedule, which started in October and required a flying prototype in December. The pressure doesn’t let up, with parts to be bought or 3D-printed, competition deadlines to be met and a final product to be ready for the fly-off challenge on 16-18 June in Snowdonia.

Indeed, it is the time pressure that Boyd finds the toughest, particularly with a team of only three, including himself and fellow engineering masters students Ang Li and Abbos Kamiljonov.

That’s not to say they haven’t added challenges of their own. One is an attempt to tackle part of the competition that has so far gone unsolved – symbol recognition. This involves drones recognising printed letters on the ground and relaying the information in real time to the team. VOLTA’s attempt to solve this problem has led them to an unprecedented step – building their own neural network.

“I think it’s quite original,” says Li, who is working on the system. “From what I heard no team has ever done that.” It is also very time-consuming. Li has to painstakingly take hundreds of photos of letters from every angle in order to train the network. “We already have more than a thousand pictures,” he says. “So all we have to do is retrain the software to be able to recognise the target on the ground.”

Neural networks

Building your own neural network typifies how competitions like the Unmanned Aircraft Systems Challenge push engineering students to experiment with things they might never have thought possible. For Boyd this is the main attraction of the competition and why it is invaluable preparation for a career in engineering.

“There are some students just sat in front of a computer designing something that’s never going to get built,” he says. “We’re actually flying and testing things, and working with our hands as well, so you get an impression of proper hardware engineering.”

For more information about the UAS Challenge, visit the IMechE page.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.