Engineering news

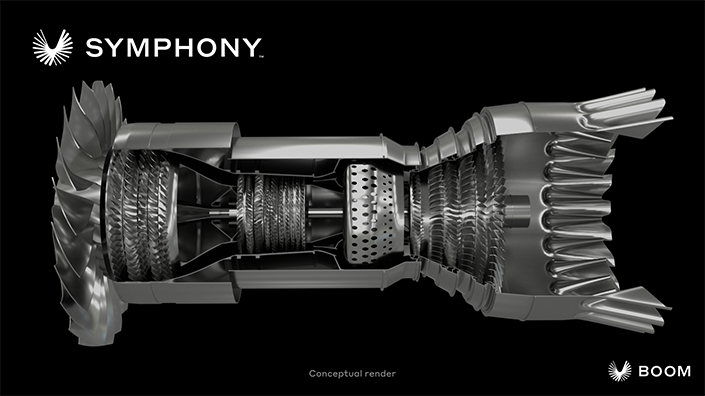

Known as Symphony, the propulsion system will be designed and optimised specifically for Overture. US firm Boom said it will work with Florida Turbine Technologies (FTT) on engine design, GE Additive for additive technology design consulting, and StandardAero for maintenance.

“Developing a supersonic engine specifically for Overture offers by far the best value proposition for our customers,” said Blake Scholl, Boom founder and CEO.

“Through the Symphony programme, we can provide our customers with an economically and environmentally sustainable supersonic airplane – a combination unattainable with the current constraints of derivative engines and industry norms.”

(Credit: Boom Supersonic)

Designed to run on 100% sustainable aviation fuel (SAF), Symphony will be a medium-bypass turbofan engine with the same basic engine architecture that currently powers all modern commercial aircraft.

Unlike subsonic turbofans however, the new propulsion system will include a Boom-designed axisymmetric supersonic intake, a variable-geometry low-noise exhaust nozzle, and a passively cooled high-pressure turbine.

Designed to provide 35,000lbs of thrust at take-off, the engine will include parts made with additive manufacturing for low weight, low part count, and reduced assembly costs.

Aimed at ‘optimal supersonic performance and efficiency’, Boom said Symphony will meet Chapter 14 noise levels, deliver a 25% increase in ‘time on wing’, and reduce engine maintenance costs.

Production of the Overture is planned to begin in North Carolina in 2024, followed by a first flight in 2027 and type certification in 2029.

Navigate a turbulent future by watching Aerospace & Defence webinars, now available to watch on-demand here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.