The first waterwheel to be patented in 138 years, the device was developed by Carruthers Renewables to combat electricity scarcity in developing countries. The firm is working with the University of Strathclyde’s Advanced Forming Research Centre (AFRC) to explore manufacturing methods.

Known as the Carruthers Wheel, the system has a unique smooth water action within the wheel, reportedly enabling ‘high efficiency at an unprecedented range of flows’. Carruthers told Professional Engineering that it can convert 80% of a river’s energy to electricity – anywhere between 10kW and 1MW, for domestic or community use. In comparison, domestic solar panels give up to 4kW.

The wheel is designed for use in waterfalls and rivers with less than 5m drop. This was previously deemed unviable and unprofitable because of the high cost of turbines for small bodies of water.

Specially designed blades allow the Carruthers Wheel to harness a river’s full potential, however, operating in a wide range of speeds and flows. Designed to be 80% standardised and 20% bespoke, the wheel’s diameter depends on the height of the weir, waterfall or cascade.

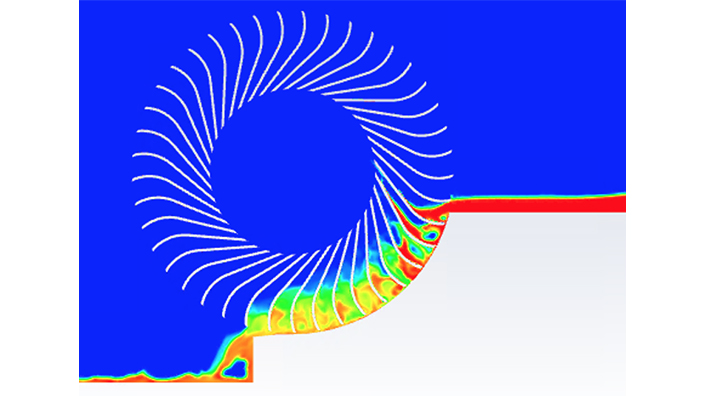

A computational fluid dynamics model of the Carruthers Waterwheel

Following production, the intention is that flatpack Carruthers Wheels will be shipped to small communities across the world, where they can be installed and maintained by local workers without highly specialist skills. “In many cases, the wheels will provide electricity to communities for the first time,” a press release for the project said.

The wheel was invented by former maths lecturer turned civil engineer Penelope Carruthers. “In the past, sites with lower than a 5m drop have been identified as a possibility for a hydropower [installation] before a decision was made to move on due to the high costs,” she said. “With millions of such sites across the world, there remains a hugely untapped resource, which has the possibility to change the lives of people in the surrounding towns and villages.”

Funded through Innovate UK, the one-year £250k project with the AFRC – part of the National Manufacturing Institute Scotland – is helping Carruthers Renewables exploit the centre’s expertise in advanced manufacturing methods before selecting the most cost-effective and sustainable way of making the wheels.

“The support we have received from the AFRC so far has been incredible,” said Carruthers. “We have been working together to secure the best manufacturing route, allowing easy install and maintenance of the wheel, along with the ability to withstand harsh environments. Above all, the goal is to make a wheel that will provide electricity to people who are currently living with no access to the grid, and the progress made so far has been ground-breaking.”

Ekaterina McKenna, business development executive at the AFRC, said: “According to a recent United Nations hydropower report, there are millions of sites worldwide with a river or waterfall of less than 5m drop, especially across Sub-Saharan Africa and South East Asia. In the small communities surrounding these sites, less than 10% of the population have access to electricity.

“The feasibility project with Carruthers Renewables is allowing us to support this growing start-up with its manufacturing engineering needs, including extreme cost-effectiveness and ease of maintenance, pushing the boundaries of what is possible, with the hope of taking the hydro-wheel to the next stage of development.”

Unlike traditional mills or turbines, the wheel does not interfere with the course of the water. The next stage of the project aims to prove the wheel’s design and positioning is environmentally friendly, from ‘eco-manufacturing’ to installation and use. Whole river ecosystems, including plants and animals, will be assessed before, during and after its use.

The feasibility study has gained letters of support from the Crown Estate, Scottish Water and the Scottish Environmental Protection Agency. A computational model of the wheel will be unveiled at the Hydro 2020 Conference in France later this year.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.