The reason being that, the further down we go into the ocean, the more inhospitable it becomes, presenting key challenges for any technologies developed to explore it. It’s a GPS-denied environment, there is tremendous pressure and with the ocean being so vast it can take a long time to get there.

Aidan Thorn, business manager of the National Oceanography Centre’s Marine Robotics Innovation Centre, recalls: “When I first started at the NOC as an apprentice over 20 years ago we had just one autonomous underwater vehicle, Autosub. That vehicle didn’t have a very long range and so was heavily reliant on a ship to get it anywhere with deep water to explore. We now have 50 vehicles and we’re increasing the range to enable operations away from infrastructure like ships through low-power sensors, mechanical and software design and novel battery solutions – the first Autosub was packed with D-Cell batteries, and one of the first jobs I did as an apprentice was taking them all out for disposal.”

Over the past two decades Thorn has seen significant development and interest in marine autonomy. And while marine science institutions such as NOC are developing next-generation marine autonomous systems (MAS) for the use of scientific research (see page 35), other industries, notably offshore and oil and gas, are also developing unmanned systems for use in inspection, repair and maintenance of their subsea assets. Indeed, BP has announced that it aims to have all of its subsea inspections performed autonomously by 2025.

In its Marine Robotics Innovation Centre, NOC is bringing together a community of partners to work collaboratively on challenges around the development of MAS. Thorn says: “Since opening our doors in November 2015, the innovation centre has had 39 partner members with broad-ranging interests and expertise in marine robotics, from platform and sensor developers to software and communications systems providers, all the way through to early-adopting end-users from industry.”

Partnering up

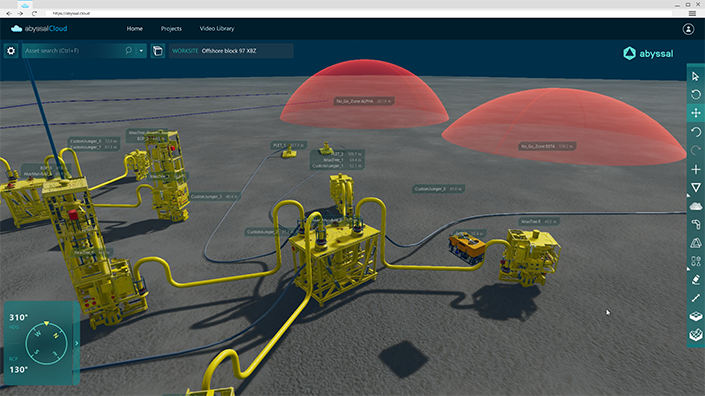

The most recent member to join the centre is Abyssal, a software engineering company with tools that provide users with a realtime 3D virtual overview of their subsea projects. Having been aware of Abyssal for some time, and impressed with its capabilities, especially in terms of simulation, digital twin and remote monitoring, NOC was eager for the company to join as a partner.

Abyssal's software provides users with a realtime 3D virtual overview of their subsea projects

“Simulation can recreate the subsea environment virtually as a field digital twin and this helps users to understand the type of environment that their MAS will be deployed into. Indeed, one of the key challenges in developing MAS is that, when you are putting your vehicle into the water for the first time, you want to be relatively clear that it’s going to work,” says Thorn.

Abyssal, which was set up in Portugal over eight years ago to support the offshore industry, has expanded to a team of more than 34 members. It provides a suite of applications that can be used throughout an offshore development project from design to decommissioning, which are all accessible via Abyssal’s Cloud infrastructure and connected via a field digital twin.

Design in context

In the initial stage, the engineering team uses the Abyssal Cloud to create a virtual 3D representation of the subsea environment in which the autonomous system will operate. To do this, the application captures, processes and integrates all relevant data into one platform from multiple sources, such as GIS, bathymetry, 3D models, imagery, point clouds and documentation systems. This allows engineers to perform tasks such as design reviews and risk assessments.

All data generated is synchronised and correlated with the subsea digital twin. It is also used in the Simulator application to perform realistic simulations.

The Abyssal Cloud is used to create a virtual 3D representation of the subsea environment

Manuel Parente, Abyssal’s chief technology officer, explains: “Essentially, we use the 3D GIS knowledge and data and apply a physics engine on top so that we can perform simulations of complex operations such as cable dynamics or virtual system integration testing.

“As well as being able to perform a larger range of situations and scenarios than we have in real life, and much faster, we can also simulate custom scenarios, such as faulty sensors and actuators, communication failures, and fiddle with the data’s integrity as well as consistency. This can prove invaluable in the development of complex and robust solutions as it helps streamline the development and shortens the time to market.”

As an example, Abyssal recently worked with a manufacturer of a new underwater intervention drone. Using the Simulator as a virtual testing environment, it could control the vehicle via the cloud.

Cristiano Carvalheiro, lead software engineer at Abyssal, says: “Having imported the vehicle’s CAD data, we then modelled its physics, actuators, such as thrusters, cameras and other sensors. Within a couple of hours – though depending on the vehicle’s complexity it can take a few days – we were able to pilot the vehicle within a high-fidelity physics-based simulation. We conducted initial hydrostatic and hydrodynamic behavioural tests and identified problems in the chassis.

“We then used Abyssal Simulator’s networking application programming interface to write a small publish-subscribe communication layer between our simulation and the vehicle controlling unit software. The simulation outputs telemetry for sensors and world state while the control unit sends the desired state for the different actuators. The vehicle engineers could now use their own controlling human-machine interface to execute autonomous commands.”

The results were disseminated via the cloud for engineers to visualise in real time in a 3D environment with the full context of the subsea surroundings. Once again, the generated data from the simulations are synchronised and correlated with the subsea digital twin.

Remote monitoring

Abyssal’s technology can also be used for training purposes as well as for remotely monitoring subsea operations. For example, it was used in the Autonomous Robotic Intervention System for Extreme Maritime Environments project, which was part-funded by Innovate UK. Led by technology company L3Harris, partnered by the University of Exeter, the project aims to develop an integrated autonomous system to derisk and enhance inspection work in the offshore environment.

The first phase of the project involved the design and feasibility testing of deploying, operating and recovering an inspection-class remotely operated vehicle (ROV) from an unnamed surface vessel. This set-up was trialled in a two-week demonstration in Cawsand Bay, Plymouth.

With nothing to actually inspect in Cawsand Bay, Abyssal joined the project to provide a virtual 3D replica of the entire seabed in which the complete autonomous inspection of a virtual pipeline could be carried out.

Software allows monitoring and remote control of subsea operations

Parente says: “The solution used the Abyssal Cloud to monitor and control the entire operation in 3D and in real time, and it disseminated the information securely to several onshore locations in London, Houston, Baku and Porto.”

Following the success of the initial proof of concept, the project has now entered a second phase that will run until spring 2021. According to L3Harris, this will see the system evolve to a pre-commercial state capable of completing sustainable inspection down to 150m water depth.

Taking AI offshore

From remote monitoring, Abyssal’s tools can also be used in command centres and control rooms where they provide onshore teams with not only a realtime 3D view of offshore operations but also enable them to remotely control and manage those operations.

Parente says: “Remote operations is where we take another step towards full autonomy. We go from monitoring to remotely operating vehicles from onshore, always with a simulation aspect underneath during technology development.

“So while we are developing a certain feature that implementation is applied in a simulated environment, which enables the end user to train, test and identify if it’s an effective implementation or not. This is especially useful during the development stage as it increases safety and efficiency.”

Abyssal’s artificial intelligence research team can then enhance this simulated and synthetic data by using its Simulator to train and test AI models in dynamic and unpredictable situations. A recent example involved a subsea inspection operation that saw the automatic measurement of marine growth on an offshore jacket. Traditionally, the operator would have used an ROV tool to clean and manually measure the marine growth thickness.

Parente says: “Using the Abyssal AI services we could automatically reconstruct the 3D environment from low-quality video footage and position these reconstructions in the 3D GIS environment. So we created a point-cloud response but we put that point cloud into context within the geographical environment, and the difference between the point cloud and the CAD model is the thickness of marine growth, and the accuracy in which we generated the point cloud is within half an inch.

“Not only are we capable of doing that just from video but we are also capable of estimating the ROV positioning within half a foot. We achieve this by using the Simulator and automatically generating synthetic data that is already perfectly annotated,” he adds.

While fully autonomous underwater vehicles promise to make subsea operations safer, more efficient and greener, tools like Abyssal’s are equipping users with the confidence to be able to get them through development and into the oceans faster and more reliably, shaping their technology for sustainable operations.

Technology to explore the ocean

Launched in 2016, Oceanids is a £16m programme funded by the UK government’s Industrial Strategy Challenge Fund that aims to develop the next generation of pioneering marine autonomous systems that will push the boundaries of how we explore the ocean.

This five-year programme is being led by the National Oceanography Centre (NOC) in partnership with the Scottish Association for Marine Science, University of Exeter and University of Southampton.

Aidan Thorn, business manager of NOC’s Marine Robotics Innovation Centre, says: “Under Oceanids, the NOC and its partners are working together on the technologies that will enable longer missions for autonomous underwater vehicles, allow scientists to explore under ice shelves, and collect vital oceanographic data in some of the most challenging and remote marine environments on the planet.”

The technologies being developed include new vehicles, marine sensors and software platforms.

The programme has already delivered three new Autosub Long Range vehicles. Autosub Long Range 1500 (or ALR1500) is an evolution of the NOC’s existing ALR technology and has been designed to deliver greater buoyancy and payload capacity, accommodating a battery pack 2.5 times larger than its sibling. This battery configuration will provide enough power for deployments with longer ranges, at higher speeds, and with the integration of more power-hungry sensors and navigation systems.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.