If his prediction comes to pass, some industry estimates say there would also need to be 274m IoT-related battery replacements every day. From a workforce and resource perspective, this vision of a connected future hardly seems sustainable – unless engineers can create far longer-lived power sources.

Until recently, the concept of an ‘eternal’ battery, one that can last for thousands of years before it needs to be replaced, would have seemed like the stuff of science fiction. But there are a number of companies and academic researchers working to make the idea a commercial reality. Last autumn, the California-based start-up NDB made headlines when it announced that it had completed two proof-of-concept tests of its eponymous nano diamond battery, elsewhere known as a nuclear diamond battery.

Lengthy lifespan

The company claims its technology, made from nuclear waste encased in artificial diamond, has a maximum lifespan of 28,000 years and could one day become a source of low-carbon power for anything that needs it – from planes to smartphones. However, some online commentators have questioned whether the battery’s formulation genuinely makes it suitable for devices that require a consistently high energy output. Sceptics will simply have to wait for the company to develop a prototype that legitimises its proof of concept. Until then, many of NDB’s proposed nano diamond battery applications will remain purely theoretical.

The idea of a nuclear diamond battery was first developed and presented by scientists at the University of Bristol in 2016. In a lecture, Professor Tom Scott explained that his team had grown a synthetic diamond that is able to generate a small electric current when placed in a radioactive field. The resulting battery is effectively self-charging in that the diamond is able to produce a charge when it’s placed in close proximity to a radioactive source. The Bristol team initially demonstrated a prototype that used nickel-63 as the source of radiation, although they later chose to utilise carbon-14, a radioactive version of carbon.

Suresh Kaluvan, inventor of the Betalight Voltaic battery

The UK’s ageing nuclear power plants contain huge reserves of carbon-14 within the graphite blocks in their reactors. Although carbon-14 is a low-yield beta particle emitter, it’s still too risky to allow it into the environment, and therefore it must be stored securely for the long term. The scientists at Bristol see a valuable opportunity in extracting and repurposing what is, at present, purely a nuclear waste material. Last year, a spin-off company called Arkenlight was formed to take on the commercialisation of the diamond battery concept.

“It is a very novel approach, which we find that people like because it’s sort of a cosmic rag-and-bone man narrative,” says Morgan Boardman, the new company’s CEO. “We are taking the carbon-14 graphite waste, which the government is developing means of dealing with – such as burying it deep in the ground – and we convert it into something that is useful and safe for humans to have at hand.”

Danger minimised

The diamond battery is a betavoltaic, which is similar to a photovoltaic solar cell, but it converts beta radiation (as opposed to light) into electricity. It’s manufactured through the process of chemical vapour deposition, which uses C-14 methane and hydrogen plasma to grow diamond films at high temperatures. The diamond used in the battery consists of thin layers of large crystalline grains – so it’s far smaller than the diamond found on rings. This multilayer structure is also designed to prevent radiation leakage and minimise the danger to human health.

“Carbon-14 beta particles, though energetic, don’t travel very far,” Boardman explains. “If you have it safely ensconced in a dense matrix, such as diamond, then the likelihood that it would emit radiation in a way that would penetrate human skin becomes negligible.”

Origins in the 1950s

Betavoltaics aren’t a new technology. They were invented in the 1950s and used to power pacemakers. The radioisotope promethium-147 was commonly used as the source of beta electrons and paired with silicon semiconductor cells. But these semiconducting materials weren’t particularly efficient in converting electrons from beta decay into a useful electric current. Scientists therefore had to use higher energy – and higher risk – isotopes in their betavoltaic formulations.

The first nuclear batteries fell out of fashion as cheaper lithium-ion batteries reached the market. Still, the testing and prototyping of betavoltaic cells continued throughout the next few decades. Better semiconducting materials were eventually paired with more benign isotopes in battery prototypes. Widetronix, a company based in New York state, developed a tritium-based battery that it was testing in military equipment monitoring applications back in 2009.

New uses open up

Unlike NDB, Boardman and Arkenlight don’t foresee their batteries being used to power cars, or even laptops. This is because they provide thousands of times less power than a conventional AA battery – although they will last thousands of times longer. Using carbon-14, Arkenlight’s power cells would take some 5,730 years to reach 50% activity and current creation. The company envisions them powering small detectors, wireless IoT devices/sensors or medical implants. Boardman also says that the company views the diamond battery as an enabling technology, meaning that it might spur the development of applications that wouldn’t have been possible without it.

“Other micropower devices harvest vibrational energy or solar energy, so they’re all dependent on outside inputs,” says Boardman. “They’re all powered from external sources or conditions. Our technology has no requirement for external sources or conditions. The next thing you’re going to have to worry about is the mechanics or the electronics breaking down and having to replace them. This is why we also have an interest in solid-state micro-electronics.”

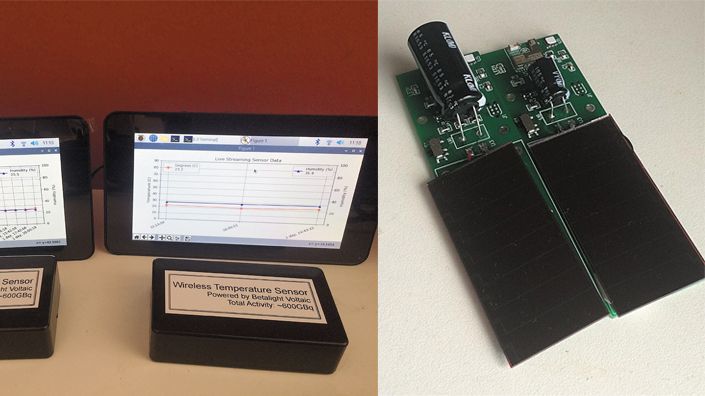

Early prototypes of the Betalight Voltaic battery developed at the University of Bristol

In 2018, Bristol researchers tested the strength and durability of their diamond batteries at the top of a volcano. In the experiment, prototype Arkenlight betavoltaics were used to power sensors inside a remote-monitoring station, known as a ‘dragon egg’. The eggs are designed to be delivered to an active volcano by drone, where they keep track of humidity, vibrations and the emissions of toxic gases. The diamond’s indelible nature also means that nuclear diamond batteries may one day assist in distributed power management for satellites or spacecraft – allowing them to lead longer operational lives in extreme environments.

In a world increasingly dependent on sensor input, Arkenlight’s batteries could provide a ‘fit and forget’ solution that enables the widespread rollout of IoT devices. According to Boardman, the technology also offers an attractive emissions saving. “With the resources used to manufacture, say, an AAA battery, we would offset nearly 2.5kg of carbon in the manufacture of an equivalent energy density of diamond batteries,” he says.

Aiming for a factory

Ultimately, Arkenlight aims to establish a factory at one of the several decommissioned nuclear power plants in the South West of England, or possibly North Wales. That way, the company has easy access to carbon-14 isotopes for battery manufacturing. Boardman estimates that, all being well, the carbon-14 batteries will begin appearing in devices around 2024.

Although they won’t provide eternal life to our phones or cars, they’re likely to be ubiquitous – consistently extending the life of small appliances. As economies increasingly come to rely on both connectivity and electrification, the advent of nuclear diamond batteries means there will be one less device to charge.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.