Rolling stock such as the Intercity-Express 3, introduced in 2000, will rattle on between Frankfurt and Cologne for another 30 years. But the fluorescent tubes lighting up the trains’ helpful on-board passenger information screens last only 10 to 15 years. And, unhelpfully, their manufacturer has stopped producing them.

So Deutsche Bahn has opted for 3D printing. It’s all about the need for speed. It took a month for the railway operator to print 200 tubes. Using injection moulds would have taken four times as long, says Florens Lichte, project leader for 3D printing at Deutsche Bahn.

Speed ultimately pushed Deutsche Bahn, like other companies, to start 3D printing replacement parts. As 3D printing has started to pick up speed, we’re starting to see businesses use it more.

Large public companies globally are expected to spend $3.1bn on 3D printing in 2020, up from $1.8bn in 2015, says Deloitte, and the market is growing at an accelerating clip. Big firms have spent 12.5% more on 3D printing each year since 2017.

By comparison, in 2015 and 2016, the market grew at only a meagre 4.6% and 5.1%. Chiefly, businesses are using 3D printing for replacement parts and prototypes now. Another burst of speed, though, could unleash 3D printing’s further latent potential.

This might mean the ability to tweak and re-engineer products directly on the assembly line. And it could bring a logistics revolution, with most manufacturing located closer to the consumer in a web of dispersed just-in-time manufacture.

This would replace the current model of bulk manufacturing, based on central warehousing and shipping, which has held up since the Industrial Revolution. The big question for now is just how long it will take until the next new burst of speed arrives to position 3D printing more solidly on the shop floor. And how engineers are going to achieve it.

Small but perfectly formed

For small batches of parts, 3D printing is already faster and more economical than using moulds. With the traditional way of producing high volumes of the same manufactured part, molten plastic or metal is injected into a steel or aluminium mould and takes its shape.

This is fast, but a particularly complex mould might cost hundreds of thousands of dollars and take a month to build. By comparison, in February, US bicycle maker Arevo took an e-bike from design to prototype in 18 days by using 3D printing – instead of a more typical 18 months.

Arevo used a new approach called continuous fibre-reinforced 3D printing. It adds carbon fibre into polymer base materials to yield a sturdier, more lightweight product, with strength more comparable to common engineering materials than to brittle thermoplastics.

There has, in fact, been a whole new industry springing up of 3D printing firms that specialise in fast prototypes – with companies like the Minnesota-based Proto Labs, Britain’s Worcester-based 3D Creation Lab, and Belgium’s Materialise. This is especially useful for small batches of parts that are no longer produced elsewhere. Siemens last year remodelled a pair of family heirlooms – motor cars from 1920 and 1922 built by Ruston & Hornsby, a Lincolnshire engine maker that is today a Siemens subsidiary.

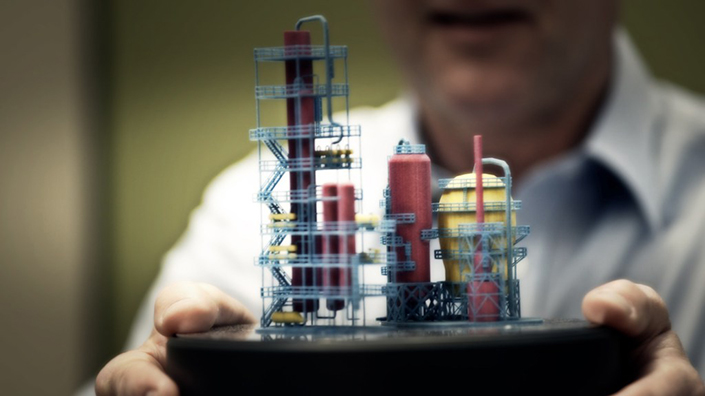

This Ruston Hornsby car was one of two restored by Siemens using 3D printing (Credit: Siemens)

It was an extreme case of a more general trend – using 3D printing to build a small number of replacement parts. To replace a steering box for which original specifications had been lost, Siemens 3D scanned, digitally restored, then 3D printed the component parts. The printing involved welding 1,000 layers of metal powder by laser over five days.

Today’s 3D-printing technology is fast enough for these small jobs, where only a small number of replacement parts, or just a single prototype, might be needed. Even the Boeing 787 Dreamliner now has 3D-printed fuel nozzles. These are printed from titanium, a pricey material about four times the cost of aluminium.

Norwegian firm Norsk Titanium prints the nozzles using a Merke 4 machine it developed in 2015. 3D printing is attractive here because it wastes less scrap titanium than the traditional approach of cutting nozzles from blocks. A 2kg part would require 6kg to print, but 30kg to cut, so Norsk prints four parts for 10 787s every month.

How long to download a car?

Right now, manufacturers are using 3D printing for small batches, and still relying on conventional technologies like injection moulding for big ones. Today “the break-even point, up to which it makes sense to do it in 3D printing with our technology, is around 100,000 parts,” says Ramon Pastor, general manager of Hewlett Packard’s 3D printing business, based in Barcelona.

“If you want to do more, then it makes sense to invest in a mould,” he explains. This break-even point is essentially because of speed, says Phil Hatherley, general manager of Siemens Materials Solutions, who oversaw the restoration of the 1920s motor cars.

“One of the challenges of modern-day metal printing machines is cost, and this is driven by the speed it takes to print the component,” he says. Until recently, printing metal in a 3D printer has used a single laser to melt together fine layers of powder, says Hatherley. Applying the powder, then joining it to the layers beneath by heating the old and new layers with a laser – a process called sintering – is the basis of additive manufacturing, another name for 3D printing.

But now the first printers with multiple lasers are starting to appear. “With four lasers, the speed of printing the Ruston component could have been improved roughly by 3.5 times,” he says.

The speed of sintering is increasing, because engineers are developing “a much better understanding of the fusing dynamics,” says Pastor. “We introduced a product at the end of 2016, and we were processing the layers in 12 seconds, but we just introduced a new product – Jet Fusion 5200 Series – that processed the same layer in eight seconds,” he says.

There can be further improvements in this direction by building better software algorithms to optimise packing. “If each layer takes five to eight seconds, and if you can build only one object, that is one thing. If you can build 100 objects in parallel, this is obviously much faster,” says Pastor.

The EOS production line making 3D printers in Maisach (Credit: EOS)

As another example, Electro-Optical Systems, a large German 3D printer manufacturer based in the Bavarian town of Krailling, developed a new LaserProFusion polymer printer last year. Its speed is more suited to that needed for serial industrial applications, says Markus Glaßer, the company’s senior vice-president.

“Instead of the laser sintering process used to date, with a single CO2-laser moving along the entire build area, this new technology uses up to one million lasers,” explains Glaßer. These can achieve a maximum total output of up to 5kW, and, for each layer, only the diode lasers are activated that match the part itself – right down to the exact pixel, he says.

The new technology “significantly shortens exposure times, regardless of the number of parts and their geometry,” he says. Developments like these ones, both at large 3D-printing companies and in research laboratories, mean additive manufacturing now sits right on the cusp of moving “from a rapid prototyping stage to becoming a true serial production technology,” says Glaßer.

Everything happens for a resin

“I think around 2015, that’s when there was a large uptick in 3D printing speed,” says Timothy Scott, an associate professor of chemical engineering at the University of Michigan. “I think this year, there’s another uptick happening exactly right now.”

Which is politely put, since Scott’s own work – laying the groundwork to speed 3D printing up by a factor of 100 – is at the centre of it. Current technology builds up a 3D-printed item a two-dimensional slice at a time, with resin printers, or a one-dimensional line at a time for solid-filament printers.

In a January journal article in Science Advances and three patent applications, Scott and his collaborator Professor Mark Burns explore how to harden 3D sections in a single shot – which is true 3D printing, says Scott. One of the contemporary speed limits in filament-type printing has been “how fast you’re able to feed the filament and heat it up, so it melts the layers below,” he says. Using a laser can speed this up, but there are “fundamental fluid mechanics issues” about how quickly you can actually bind two layers.

Printers can handle more complex designs than before (Credit: HP)

A step forward from this is an approach called stereolithography, which, instead of building up an object by slices or lines, starts with a three-dimensional resin vat.

Polymerisation is the process in which the resin goes from a liquid to a solid, and it is a process that is inhibited by oxygen. So you have a membrane that is somewhat permeable, and a region adjacent to the membrane layer where polymerisation doesn’t happen, where the resin can be shaped.

This approach was first explored by Carbon, a Silicon Valley company headed by Joseph DeSimone, a chemical engineering professor at the University of North Carolina at Chapel Hill and North Carolina State University.

Before Carbon’s M1 printer appeared in 2016, printing “something the size of my fist took about five to eight hours – and they could get this down to 20 minutes,” says Andrew McDowall, a 3D-printing designer working at Middlesex University in London.

The South Carolina company 3D Systems introduced a printer it calls Figure 4 in 2016 along similar lines. “They looked at their portfolio, and it turns out one of their patents describes something similar to what Carbon’s doing. Figure 4 refers to the fourth figure in that particular patent,” laughs Scott.

Michigan-based EnvisionTEC also produces printers using a similar approach, especially for use in dentistry. Carbon’s printers have been popular for making custom midsoles for running shoes. There are certain issues with it. “The membrane itself is thin, and as a result it’s not really robust and it tends to buckle up, but regardless it is a really good idea,” he says.

Different wavelengths

Scott’s lab also begins with vat polymerisation – you start with a vat with resin in it. But instead of using oxygen to inhibit polymerisation in the window area which the printer is shaping, it uses light.

One wavelength of light prevents the polymerisation reaction, while a second wavelength speeds it up. When you direct these two wavelengths “tens of microns” apart, you get a continuous window you can shape. And you can go much faster than by using oxygen to inhibit polymerisation. “It’s a pretty cool idea, actually it’s amazing that it works at all,” says Scott.

A printer applying this approach could knock off “a couple of metres an hour in linear fabrication rate,” he says. It’s a promising approach, in which the issues still to solve involve making interesting resins photo-reactive and increasing the depth to which light will penetrate. There are also mechanical issues to be puzzled through.

“If you go too fast, it gets too hot and it starts to smoke – yeah, I know, right,” he says. “Saying it’s just an engineering issue is dismissive – there are genuine non-trivial issues that limit how fast we can go,” says Scott. But the approach still offers a hundredfold speed increase on what’s currently on offer.

Going for a quick spin

Another take on the photo-sensitive polymers idea is a Replicator, named after Star Trek and being developed by Hayden Taylor, assistant professor of mechanical engineering at the University of California, Berkeley. Taylor and his colleagues think of their Replicator as a computerised tomography scan in reverse.

In the middle is a photo-reactive polymer, which is turned by a rotating motorised cylinder. Around it, instead of taking cross-sectional X-ray images of different slices, a video projector projects a series of images on to the resin in the middle. This method has so far produced printing times “of 30 to 120 seconds” for several different centimetre-scale objects, with features as small as 0.3mm, say Taylor and his co-authors in a March article in Science. With resins, you also “can do a lot of engineering with the material itself, and make it flexible, hard, transparent,” says McDowall.

Another speed consideration with the new resin technologies involves post-processing tasks, such as taking off scaffolding, and “clean it and polish it and whatever needs doing to it,” he says. “They don’t like to show you that part,” he says.

Deutsche Bahn, meanwhile, thinks that 3D printing will cut the manufacturing time for its trains’ fluorescent tubes by 95%. Coat hooks, headrests and fan propellers have followed, with 3D printing letting the rail provider fit the right spare parts to get trains back into circulation more quickly. The rest of the world can only follow in its tracks.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.