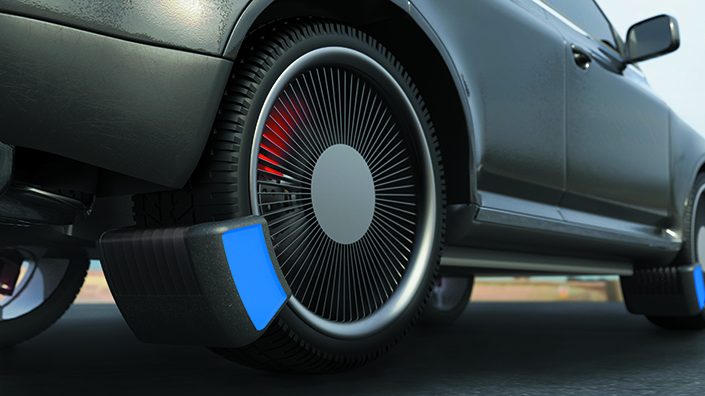

The device, bolted to a vehicle’s underbody, is designed to catch a shower of tiny tyre flakes created on every journey. After years of research and prototypes, the company behind it – the Tyre Collective – started road trials in September.

The results will reveal how the invention performs when up against natural air flow, road conditions, turbulence and, importantly, human behaviour (drivers are asked to clean out the tyre dust once it’s collected).

Success will accelerate a project that’s already won a James Dyson Award, secured three Innovate UK grants, and has taken its founders on a ride from a university lecture room to offices at Somerset House in central London.

A working prototype currently being tested on the streets of London

Problem under our wheels

Air pollution is a big killer, causing tens of thousands of premature deaths in the UK and millions around the world. New research suggests that out of every 1,000 humans on earth, 973 regularly inhale toxins – dirty air that exceeds the World Health Organization’s threshold.

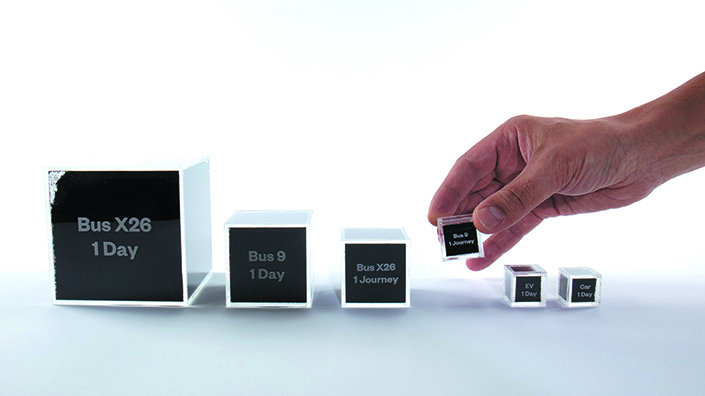

According to the Tyre Collective, tyre wear is now the second-largest microplastic pollutant after single-use plastic. It says that in Europe alone more than a million tonnes of tyre particles are produced each year, ending up in waterways, in oceans, on plates and inside lungs. A single van can create 2kg in a year. If you could turn the daily tyre dust of a double-decker bus into a black snowball, explains Hugo Richardson, a mechanical engineer and one of Tyre Collective’s founders, you’d be holding something the size of a grapefruit.

Tyres contain a complex mix of natural and synthetic rubber, containing plastic.

“Everyone knows they have to change their tyres because they wear down,” says Richardson. “But no one thinks about where all that rubber and plastic goes.”

One group of friends has been thinking about this problem, a lot, since 2019. Richardson, Siobhan Anderson and Hanson Cheng (along with a friend who’s now left the collective) met while completing masters degrees offered jointly by Imperial College London and the Royal College of Art.

Small particles, big problems – the Tyre Collective show how much tyre dust is produced by different vehicles each day

Diversity sparks innovation

At first glance, they had little in common. They were born in different countries. Their backgrounds ranged from engineering to architecture to kinesiology. But this diversity – this clash of disciplines – helped them look at the problem of air pollution, and more specifically tyre wear, through a fresh lens.

Working on their final group project, they spent three months building an early prototype, using a rig and a Brompton bicycle wheel, forcing it to “skid” and throw up tyre dust. Their “eureka moment” involved rubbing a balloon and watching tyre particles, which became charged through friction, stick to it like iron filings to a magnet. The device they built involves electrostatic plates that catch particulate matter (PM).

By September last year, they turned a laboratory rig into an on-vehicle prototype. Working with Volvo and CEVT (China Euro Vehicle Technology) innovation centre, both part of the Geely group, the Tyre Collective clocked up more than 3,000 miles of on-vehicle testing in Sweden. They tried different ways of mounting the device, studying its efficiency and the powerful forces involved. They also analysed what was being captured, and how much of it proved to be tyre dust.

To road trials, and beyond

Seeing their idea leap from a sketchpad to the belly of a car filled Richardson and his friends with confidence. They’ve since filed UK and international patents for their design, moved away from 3D printing towards market-ready materials and assembly, built a custom power supply and partnered with Zhero, an east London logistics company that shares their vision and offered its vans for the road trial.

“We’re excited to test the whole system,” says Richardson. “We’ll be looking at capture efficiency, and our lab tests are ready to go.”

The collective hopes delivery vehicles and buses will be first in line to use their device. Both rack up stop-start miles along predictable city routes, where air pollution peaks. At first, owners and operators will be able to buy retrofitted devices. But in the long run the team hopes to see the device as an add-on offered by car manufacturers, customised to blend into the overall vehicle design.

Richardson says the trial will also help them better understand user behaviour and answer questions around what to do with the tyre dust once it’s gathered. He imagines a wide network to collect and reuse it, making anything from new tyres to clothes. The team has done some early experiments in this field, and has just won a Terra Carta Design Lab Award for its plans to create a circular system by upcycling tyre wear.

Early experiments helped the team design their device

A step in the right direction

There’s debate about how big a problem is tyre wear, but what’s not in dispute is that it’s on the rise. As batteries replace internal combustion engines, vehicles are getting heavier, which means more friction for tyres. EVs also deliver more torque, which leads to faster acceleration and sharper turning or braking.

Professor Frank Kelly, of the Environmental Research Group (ERG), says that capturing tyre particles before they escape is a good example of the kind of technological fix that is needed in urban areas.

The ERG, a 30-year-old research organisation that Kelly leads, helped London implement its low- and ultra-low emission zones, along with the inner-city congestion charge, which are all widely credited with delivering a steep drop in air pollution. One of ERG’s key focus areas now is studying microplastics and understanding the health risks they pose.

Because companies use secret formulas to manufacture tyres, using different polymers, groups like ERG are in the early stages of studying what kinds of particles are being released and how toxic they are, explains Kelly.

“Approximately 65% of particulate pollution coming from a modern vehicle is not coming from the tailpipe,” he says. “That means, even if every vehicle in a city like London becomes electric, we’d still have a particle air pollution problem.”

Finding new challenges

Kelly says that, after smoking, air pollution is one of the UK’s stealthiest killers, causing up to 34,000 premature deaths. Some estimates are higher. Transport for London says the city saw more than 4,000 deaths linked to air toxins in 2019.

The fact that most modern tailpipes aren’t spewing out the toxic fumes they used to is thanks to decades of innovative engineering, regulations (such as the EU standards) and enforcement. Smarter fuel injection, engine control systems, on-board diagnostics, catalytic converters and particle filters have led to far cleaner petrol and diesel vehicles.

Andrew Fraser, chairman of the automobile division of the Institution of Mechanical Engineers, who spent more than three decades developing lower emissions solutions at Ford, calls these interventions “stunning”.

“Transport engineers should be proud of what’s been achieved and should look forward to the future with huge ambition,” he says.

Drivers will need to empty out containers once they are full

Context is key

Fraser is a technical consultant at the Zemo Partnership, a non-profit-making organisation in the zero-emission mobility space. He compares non-tailpipe pollution to bumps appearing at the bottom of a swamp that’s been drained.

The three most prominent causes of non-tailpipe pollution are tyres, brakes and the erosion of road surfaces.

Kelly says that modern brakes are partly contained systems that don’t release as many particles into the air as tyres do. Fraser adds that regenerative braking used by EVs, which captures and transfers energy, has decreased brake-pad wear to the point where some manufacturers are concerned about corrosion or glazing caused by inactivity. And some modern cars, such as those in VW’s ID range, are returning to rear drum brakes, which are more effective at capturing brake dust.

At the same time, there’s ongoing research into making roads more durable. Kelly says that, while more durable roads will help with particle pollution, engineers using recycled plastic or old rubber must be careful not to introduce dangerous microplastics into the mix, or allow them to be generated through road abrasion.

No easy answers

When it comes to tyre dust, things get complicated. It’s more difficult to catch, there’s less research to rely on and there’s debates about how dangerous it is.

According to research groups such as Emissions Analytics, tyre wear can be nearly 2,000 times worse – or more hazardous – than tailpipe emissions.

But Fraser warns that any interventions or advances to materials used should not come at the expense of safety. Tyres and brakes have become sophisticated components of a modern vehicle, and just 1m of braking distance can mean the difference between a crash or a near-crash. A lot of the tyre research over the past 50 years has centred around safety, improving friction and noise levels, and minimising energy consumption (especially important for electric vehicles).

Fraser says research has shown that tyre dust and other non-exhaust PMs make up a fraction (less than 10% and, in some instances, less that 1%) of the overall air pollution problem. He adds that it’s important to consider the size of the tyre particles and how many of them qualify as PM2.5, the tiniest ones, which are typically inhaled. The Tyre Collective claims that, when it comes to road transport, tyre wear accounts for half of airborne particles.

For Fraser, this context is important as engineers search for answers. He writes about the need for accurate comparisons and measurements – increases in percentage versus absolute levels of pollution – in an IMechE contribution to the Chief Medical Officer’s annual report, due to be released soon.

How one of the devices could look in future

A shifting frontline

Kelly’s priority, meanwhile, is to understand how dangerous the particles are. “We don’t know how serious this is. Tyres are chemically complex and the research is just starting to address the toxicology of tyre wear. Ultimately, we need durable tyres that don’t release toxic particles, or we need to get off the ground,” says Kelly. “Until we get there, we need to capture those particles before they leave the vicinity of the vehicle.”

Kelly believes engineers have “worked miracles” to get tailpipe emissions under control.

“The next generation need to tackle new issues around brakes, tyres and road surfaces.”

With the worldwide push to ban internal combustion engines, and more buses and taxis already switching to batteries or hybrid, the frontline in the battle against air pollution will shift. And, with as many as 10 million people dying each year from the effects of air pollution, it’s a battle in which engineers will play a crucial role.

Moonshots and quantum leaps

Kelly and Fraser see many areas in transport ready for innovation, from the construction industry to refrigeration trucks, which are a key link in the world’s food chain but tend to use diesel-powered compressors.

Fundamentally, brakes and tyres haven’t changed in over a century, says Fraser, wondering if there’s a “quantum leap” waiting to disrupt these and other mechanical systems. New ideas could spill over onto train tracks or into underground tunnels, where metallic brake dust remains a problem. There’s research into hydrogen-powered vehicles and, of course, the new transport dimension: the sky.

Through their work and innovation, engineers such as Hugo Richardson are sending a clear message: challenge accepted.

Having initially been taught to design against failure, Richardson is now embracing the start-up mentality of failing fast and looking at the problem from new angles.

“We started with a moonshot, but now people are approaching us,” he says. “If your idea is grounded in reality and solves a problem, it’s worth exploring. It’s a long road, but it starts with awareness.”

Awareness and innovation. Like a small device clinging onto a delivery van, catching the tiny black flakes few people ever think about.

Navigate a turbulent future by attending Aerospace & Defence (28 November – 2 December). Register for FREE today.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.