Engineering news

British engineers are working on a demonstration project to integrate a kinetic energy recovery system (KERS) into a manual gearbox of a performance car.

The £4.3 million Technology Strategy Board-funded project will see the lightweight, race-proven Flybrid KERS technology from Torotrak installed into a Lotus. The project will progress Torotrak's strategy of delivering production ready KERS technology for the mass car market, while improving relationships within the supply chain.

Lotus will lead the project, providing donor vehicles, development support, and purchasing Flybrid hardware to test the installation. Flybrid will design, develop and manufacture bespoke flywheel KERS hardware for integration with the Lotus manual transmission. Green technology specialist Productiv will offer production support throughout design and development. And there will also be a number of key subcontractors working closely with the consortium on transmission integration and optimum control implementation.

Jeremy Deering, Torotrak’s chief executive said: “This project plays to our strengths – low carbon engineering excellence, supply chain development and low volume prototype manufacture as a precursor to eventual, more widespread, licensed production for passenger cars.”

Jon Hilton, Torotrak’s commercial director and Flybrid co-founder, added: “The opportunity to integrate Flybrid KERS into a lightweight, agile performance car will be a step towards integration in higher volume manual transmission compact cars in the future.”

The demonstration project will run for 24 months. The funding award has been made under the Technology Strategy Board’s Low Carbon Vehicles Integrated Delivery Programme 10: ‘Building an Automotive Supply Chain of the Future’.

What is KERS?

What is KERS?

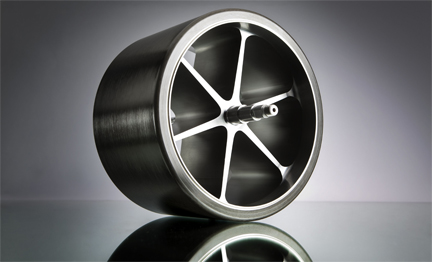

Flybrid’s core technology is a flywheel-based kinetic energy recovery system, for use in mobile applications.

The mechanical hybrid system uses no batteries, and works by recovering kinetic energy during braking which would otherwise be lost, and then returning the stored energy to assist the vehicle under acceleration.

The Flybrid KERS is described asd lightweight and compact, and its ability to store energy and deliver power does not deplete during use. The net result of Flybrid KERS in most vehicle applications is a significant reduction in fuel consumption, however the technology can be applied to deliver significant additional performance as well as fuel saving.