What happens when engineers explore the possibility of replacing tried-and-true but cumbersome in-house code with multiphysics simulation software? Nuclear engineers began to ask this question at the Computational Techniques Branch of Canadian Nuclear Laboratories (CNL), Canada’s premier nuclear science and technology organisation.

In the field of nuclear engineering, where research focuses on improving the safety, efficiency and economics of reactors, mature and robust in-house computer codes are frequently used for modelling studies. Unfortunately, the need to comb through many lines of code to investigate the potential effect of a minor adjustment to a system is a real barrier to innovation. As an alternative to modifying mature or legacy codes, a multiphysics platform provides an environment that allows engineers to explore changes in data and modelling methods without the complications of adapting lengthy code.

Andrew Prudil, fuel safety scientist at CNL, is at the center of research that enlists simulation software to find ways to improve the established, seemingly immutable design of nuclear reactors.

“Essentially, nuclear science is material science, but with additional considerations for the effects of radiation,” Prudil explains. “The materials we study include the nuclear fuel, as well as the constituents of some of the surrounding components.”

Nuclear fuel: a complex materials science problem

Ultimately, Prudil enlisted multiphysics software to create an awe-inspiring mathematical model that includes a staggering number of physical phenomena. His modelling work includes a representation of a nuclear fuel pellet including heat transport, structural mechanics deformation, mechanical contact, pressure buildup due to fission gas release and microstructural changes due to grain growth, radiation damage and burnup. He also modelled the behaviour of the cladding around the nuclear fuel.

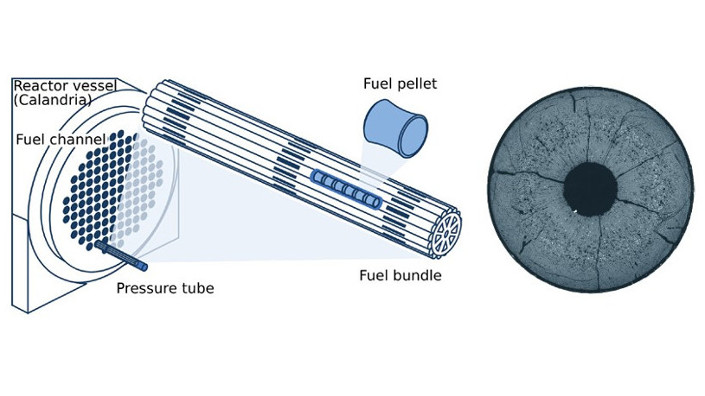

In a nuclear reactor, pristine nuclear fuel pellets (Figure 1) are placed inside the cladding, or sealed metal tube. Upon irradiation, these fuel pellets increase in temperature and transfer heat to the sealed metal tube, which in turn transfers heat to water. This hot water is eventually used to produce steam in order to generate electricity, mirroring the process that takes place in conventional power plants.

Figure 1: Left: Diagram showing the location of fuel pellets in a fuel bundle. Right: Transverse micrograph of a fuel pellet showing the microstructure produced during operation.

Upon irradiation, a fission reaction drives heat production within the fuel pellets, resulting in high temperatures, high thermal gradients and thermal expansion. There are also nuclear-specific phenomena to consider, as the products of fission accumulate in the fuel pellets.

Figure 1 shows the complicated microstructure of a nuclear fuel pellet after sustained high-temperature operation. The initial as-fabricated grain structure remains only on the outside closest to the coolant where the temperature is the lowest. At slightly higher temperatures, the grains grow (coarsen), forming a region of equiaxed grain growth. At the highest temperatures, a vapor transport mechanism enables the porosity in the fuel to migrate following the temperature gradient (toward the center) forming a central void and leaving long columnar grains in its wake.

Of these effects, cracking occurs inside the ceramic fuel. There is also contact between the ceramic and the metal cladding. Radiation damage needs to be considered, as high energy fission products such as gamma and neutron radiation change the microstructure of all materials. There is also macroscopic swelling, as fission is the splitting of one atom into two and two atoms take more space than one.

Furthermore, two fission products, the noble gases xenon and krypton, are inert and form bubbles inside the fuel pellets (Figure 2).

Figure 2: Micrographs showing the development of fission gas bubbles on the grain boundaries of uranium dioxide fuel. With increasing burnup, left to right, the bubbles become larger and more interconnected. White, Development of grain-face porosity in irradiated fuel, J. Nuc. Mat. 325, 2004, www.sciencedirect.com/science/article/pii/S0022311503004616.

There are also corrosion issues to consider as high-temperature water in a radiation environment leads to the formation of radiolysis products, which cause corrosion on the outside of the cladding.

Preventing fuel failure

Because the properties of nuclear fuel pellets change dramatically as they are irradiated, engineers rely heavily on models to predict fuel performance parameters like peak temperature, gas pressure and cladding strain to interpolate between available experiments. Similarly, knowing how any design change could manifest in a radiation environment requires extensive modelling work and validation with physical measurements.

One of the primary motivations for Prudil’s research was to model the deformation of the cladding and obtain a better estimate of cladding strain, as it is a significant mechanism of fuel failure. Once a model for strain of the cladding was created, the system could be optimised virtually. Optimisation strategies include making a direct change to the fuel, the fuel to cladding gap, or how the fuel is treated once in the reactor.

“It’s relatively straightforward to build a model,” Prudil says, “but less straightforward to know what the correct material properties are to put in that model, especially when they evolve with time and radiation exposure.” After completing a new model, he compares the simulation results to experimental results to assess the quality of his predictions.

Changing the fuel itself is an attractive approach to improving a nuclear reactor, as nuclear fuel is designed to be replaced. This is cost effective, as no parts of the reactor would need to be updated: The engineers could simply feed the system the new fuel when it is time to refuel the reactor.

“Therefore,” Prudil says, “our top challenge is accurately describing the materials in question.”

Coupling several physical phenomena in one model

Using the COMSOL Multiphysics® software, Prudil created the Fuel and Sheath Modelling Tool (FAST) to capture the complex heat transport, solid mechanics and material behaviour of the nuclear fuel, cladding and the gap between the fuel and the cladding. Figure 3 shows an example of the temperature profile generated for the pellets and cladding.

Figure 3: Simulation results from the ‘Fuel and Sheath Modelling Tool (FAST)’ showing temperature throughout the cladding, fuel pellets and pellet-pellet gaps.

“Using COMSOL software,” Prudil says, “I don’t have to worry as much about the numerics and programming – I’m able to directly approach the math and the physics rather than worry about the solution process and the post-processing. There’s less overhead than what’s usually associated with numerical modelling using an in-house code.”

Prudil also obtained simulation results from FAST the show hydrostatic pressure, von Mises stress and axial creep throughout the cladding and fuel pellets (Figure 4). The distribution of these fields is the result of design parameters such as the length-to-diameter ratio and chamber dimensions as well as operational considerations like power level and coolant temperature.

Figure 4: Simulation results from FAST showing hydrostatic pressure (top), von Mises stress (middle) and axial creep (bottom) throughout the cladding, fuel pellets and pellet-pellet gaps.

Simulating the evolution of grain boundary porosity

To extend the modelling tool and shed light on the performance of the reactor in a different way, Prudil modelled the diffusion of gas out of the fuel grains and then the formation and movement of bubbles on the grain boundaries (Figure 5) using the equation-based modelling functionality available in COMSOL®.

Upon irradiation and the chemical change of the nuclear fuel, gas seeps out of the fuel grain, forming bubbles. These bubbles then move around and coalesce (Figure 5). In a traditional phase field, the volume of the fuel grains would be modelled. The novelty and power of this technique comes from ignoring the solids and only modelling the moving surface between the solids and gas. This turns a 3D problem into 2D and significantly reduces the computational resources required.

The model uses two coupled weak form equations on the surface of the grain, one for the distance to the bubble surface, and the other for the chemical potential. Knowing how much gas comes out of the fuel allowed Prudil to calculate the thermal conductivity and gas pressure inside the fuel element. The results from this analysis allowed Prudil to determine other key indicators of fuel performance. This set of calculations serves as a nonlinear representation of fuel degradation (Figure 6).

Figure 5: Simulation, left to right, of formation, movement and coalescence of gas bubbles on the grain boundaries.

Figure 6: The fuel degradation process.

From the simulation, it is possible to approximate if the pressure is sufficiently low, such that the fuel can continue being irradiated — an insight with great implications for safety.

Simulation drives innovation in fuel technology

By using multiphysics simulation, engineers at CNL were able to create a useful tool, and clear the way for faster design iteration and innovation. Prudil sees multiphysics simulation informing other areas of development in nuclear engineering, such as the development of accident-tolerant fuel. The interest in designing fuel that is resistant to severe accident scenarios represents an opportunity for engineers to completely rethink fuel.

In the long term, Prudil also sees simulation software playing a role in the development of small module reactors, which would represent a paradigm shift in nuclear reactor design toward smaller, easier to build reactors and potentially reduce the high capital costs of reactors. Small module reactors could be made of new materials and have new geometries and safety paradigms, a departure from the decades-long trend of ever-larger nuclear reactors.

Meanwhile, the complex representation of existing reactors Prudil has already created continues to lend valuable insight into the many layers of complexity of the nuclear reactor.

![Andrew-final[2] Andrew Prudil, fuel safety scientist at CNL.](https://imechewebresources.blob.core.windows.net/imeche-web-content/images/default-source/default-album/andrew-final-2.jpg?sfvrsn=43d68512_0)

Andrew Prudil, fuel safety scientist at CNL.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.