For a growing number of companies and agencies around the world, the natural satellite is increasingly seen as a bountiful source of useful materials. Last September, NASA invited commercial proposals for the collection of lunar resources, pledging to “fuel a new era of exploration and discovery that will benefit all of humanity”.

Once seen as a barren rock, the Moon is now known to comprise a huge number of valuable resources. The materials on or near its surface could be transformed into lunar bases, and air for occupants to breathe. They could enable further exploration of the solar system. One day, perhaps, they could be found in our mobile phones and other technology.

The lunar surface is an unforgiving place, however. Unprotected by an atmosphere, machinery faces intense heat from the Sun on one side and cryogenic freezing on the other. Electrostatically charged dust particles are as abrasive as sandpaper. Larger high-velocity particles, moonquakes and solar winds are just some of the other environmental issues – and quick repairs are out of the question.

Extracting material presents some of the biggest engineering challenges imaginable to would-be 21st-century prospectors. Here is how the lunar gold rush could play out.

Digging in

The Moon’s surface is mostly made of regolith, a fine soil containing some larger rocky fragments. Formed through meteorite impacts, solar wind and some volcanic eruptions, it is known to include a number of mineral resources. Iron, aluminium and titanium are all present, as are minerals less readily available on Earth, such as anorthite. There's helium-3, which could be used for fusion energy (some experts are doubtful). Ammonia has been found, and could one day be used to produce nitrogen for agriculture.

Regolith could be collected by machines such as NASA’s Regolith Advanced Surface Systems Operations Robot (Rassor). The machine has digging bucket drums at both ends of its body, which rotate in opposite directions to give enough traction on one end to let the opposite side dig into the soil.

The Rassor, seen here in testing, has unique features to help it dig into the regolith (Credit: NASA/ Kim Shiflett)

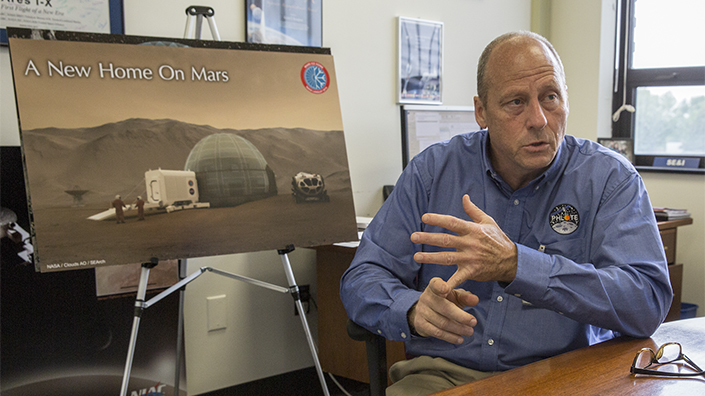

The unusual technique is due to a unique challenge of extra-terrestrial operation. Until they can be built in situ, mining machines must be light enough for launch but heavy enough to work in the low lunar gravity. “You’re very mass constricted,” says Kevin Kempton, a manager in the NASA Space Technology Mission Directorate. “When you don’t have much mass, it can be very hard to dig into the surface.”

Other robotic technology will be trialled by the successful respondents to NASA’s 2020 solicitation. Colorado’s Lunar Outpost, Ispace Europe, Ispace Japan and California’s Masten Space Systems aim to collect regolith and leave it in place for the space agency to retrieve, using small and lightweight rovers to traverse the surface.

The Ispace rover, for example, has four wheels with prominent ridges to grip the surface. Covered in solar cells, the rover will collect 360º HD video and map the terrain as it searches for materials using radar and spectrometers. Eventually, the company aims to introduce autonomy and ‘swarming’ capabilities, as well as drills and manipulators, and the resilience to withstand the extreme cold of the lunar poles.

Permanent darkness

Unlike Earth, which tilts more than 20º relative to the Sun, the Moon is only tilted about 1.5º. This means that some areas, particularly the bottoms of craters, have been in permanent frozen darkness for billions of years. Lunar nights also last for 14 day-night cycles on Earth, plunging one half of the surface into deep freeze.

This causes huge challenges for robot engineers, says Kempton. Machine lubricants can freeze, so rovers use a significant amount of energy heating gearboxes and other moving parts. One potential solution is making moving parts from bulk metallic glass, which has very high wear resistance in extremely cold temperatures.

NASA's Kevin Kempton (Credit: NASA)

Even if robotic miners can keep operating, however, breaking the surface will be no easy task – especially when dealing with the most immediately promising material on the Moon. Believed to have been deposited by comets or asteroids, water is particularly abundant in ice at the poles. It could eventually be melted and purified for astronauts in lunar bases, but its first big application will be undergoing electrolysis to generate hydrogen and oxygen for rocket propellant.

“The water mixed with regolith is going to be like granite,” says Kempton. Through his Game Changing programme at NASA’s Glenn Research Centre in Ohio, engineers are investigating scoops that vibrate at ultrasonic frequencies to generate the reaction forces needed to dig in. But, given the immense environmental challenges, a less mechanical approach might have the most success at extracting water.

Eternal sunshine

Following a 30-year career in aerospace, George Sowers is now a professor at the Colorado School of Mines. Focused on extracting water for conversion into fuel, his ingenious low-energy concept, funded through grants from the NASA Innovative Advanced Concepts (NIAC) programme, exploits the unique conditions in craters at the lunar poles – frozen darkness at the bottom, but eternal sunshine above the surface.

The system includes tall mirrors, which will reflect sunlight down onto a ‘capture tent’, a circular structure with a transparent lid set up on the surface. The light will heat the surface, the first metre of which is believed to contain most of the ice. In the extreme cold and hard vacuum, the ice’s phase change will be from solid to vapour. Sowers hopes to collect the vapour with ‘cold traps’, cylinders mounted on rovers around the rim of the tent.

The ‘ice haulers’ would then drive the ice to processing plants to be purified – removing unwanted chemicals such as hydrogen sulphide – before electrolysis and liquefaction into fuel.

After one patch of ground is depleted, the rovers would use trailer hitches to drag the skid-mounted tent around and over to another spot, like “cutting biscuits out of dough”.

Rovers around the rim would collect the vapour and move the system across the surface (Credit: George Sowers and Matt Olson)

Sowers suggests that lunar mining could follow a similar trajectory to the process on Earth.

“Early in Colorado history, where I am, the gold miners were able to pick gold nuggets out of the streams,” he says. “Today in Colorado there’s hard-rock gold mining… blasting, grinding up rock, processing it with sophisticated processing. There are even companies that are going back into the old mine tailings from 100 years ago, and reprocessing it because the technology is better.

“So there’s really no limit, technologically, to getting all the ice, no matter how deep it is, right? What my method is intended to be is the analogue of the gold panning.”

Other projects are exploring similar ways of extracting water and other volatile materials from the surface without failure-prone mechanical digging. Trans Astronautica Corporation (TransAstra), another beneficiary of the NIAC programme, aims to build giant ‘sunflower’ reflectors, which will reflect sunlight onto solar arrays on the surface. Founder Joel Sercel says 1km towers will eventually be able to access constant sunlight, but the first will be closer to 100m, where the reflectors will be in the light about half of the time.

The solar cells will power autonomous ‘beetle’ rovers, which will use a patent-pending process known as radiant gas dynamic mining to heat the ice. The method combines radio waves, microwaves and infrared to heat the surface before catching the water in ‘cryotraps’, where it can be stored as liquid.

New possibilities

Material collection is just one part of the in-situ resource utilisation process, which will take raw materials, convert them, and use them in a variety of applications. While purification and electrolysis of water are well-proven processes, other materials will need a more creative approach.

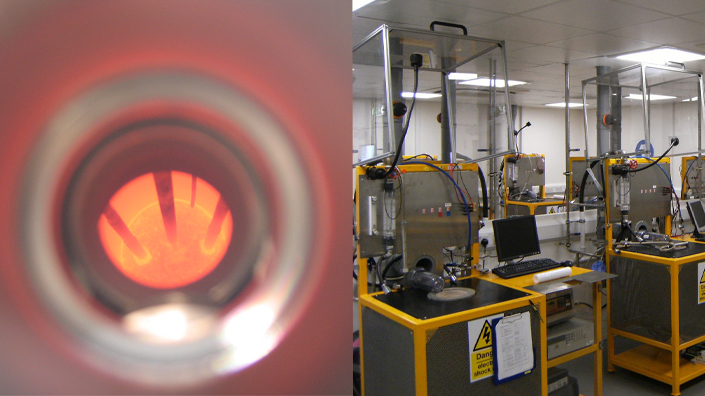

Rotherham firm Metalysis, for example, is working with the European Space Agency (ESA) to bring its electrochemical metal processing to the Moon.

On Earth, the company takes metal oxide and treats it to produce metal powders. On the Moon, the metal could be used for construction, while ‘waste’ oxygen might be used as propellant or life support.

In the terrestrial process, which works for roughly 50 elements, the metal oxide is one electrode while graphite is the other. A ‘bath’ of electrolyte is heated up to 1,000ºC and a voltage applied between the two electrodes, removing oxygen from the oxide and leaving metal powder at the other electrode.

Metalysis is bringing its process to the Moon

“How can we extract the most amount of oxygen, with the lowest amount of consumed power? From a payload perspective, it needs to be as light as possible and low-footprint as possible,” says Metalysis managing director Ian Mellor.

The company is working with Oxfordshire firm Added Value Solutions to put its technology into a small-scale demonstrator – something about the size of a washing machine, says Mellor. As with other projects, it will need to survive launch and the lunar conditions, and the process needs to be automated.

Once metal and oxygen are separated, the solid could be used for 3D-printed construction. The Metalysis team is working with ESA to investigate whether the powder will need further separation, or if it could be used as a whole.

Regolith itself could be printed to create lunar habitats, but such a process has its own challenges. “The problem is you need a binder, or you need to sinter it using microwaves or something,” says NASA’s Kempton. “It’s not like cement on Earth, where you can just add water.”

Researchers are working hard to find a solution, which might come from an unexpected source – experiments at Østfold University College in Norway used urea, present in urine, as a plasticiser – but experts agree that creating fuel will be the most immediately economical application for mined materials.

“It’s really the economics that makes the space sources of propellant important,” says George Sowers. “It lowers the cost of everything that we’re currently doing. It also opens the doors to things that we can’t do today.” His research, being published in the journal New Space, shows that lunar propellant could save an astronomical $12bn per Mars mission – “suddenly that cost can come within the threshold that makes it affordable”.

Lunar legacy

Mining and resource utilisation projects are gathering pace, as NASA plans to return humans to the lunar surface through the Artemis programme by 2024. The four participants in its material collection project aim to arrive on the Moon in 2022 and 2023, while others hope to join soon after.

TransAstra hopes to test its technology on the Moon within five years and operate a base within 10. The company is collaborating with partners including Blue Origin, founded by Jeff Bezos, giving it a good chance of success. Elsewhere, ESA-backed Metalysis hopes to demonstrate its process on the Moon within five years.

How a lunar base could look (Credit: ESA, Foster + Partners)

In the rush to exploit this vast new resource, there are some concerns about humanity’s destructive environmental legacy stretching beyond Earth. In a TEDx talk in 2017, Dr Alice Gorman – a ‘space archaeologist’ also known as Dr Space Junk – raised the issue of mining activity changing the surface of the Moon and damaging heritage sites such as the Apollo 11 landing zone.

“Drawing on my background as a heritage consultant in terrestrial mining industry, I think what we need to do is to institute an environmental impact process for lunar industry,” she said. “When we started dismantling the Earth we didn’t know what we were doing. We have no excuse now.”

Space exploration and resource utilisation must be balanced with sustainable policies on Earth. Time is running out to prevent the worst effects of climate change – but with commercial will and international collaboration it is possible. One day, though, we might be glad to know that the Moon can support us as we venture beyond.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.