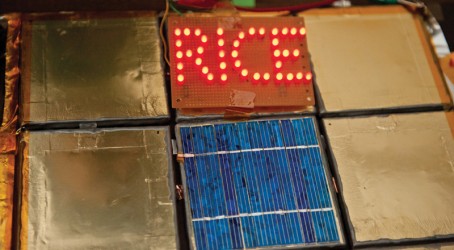

Just recently an array of light-emitting diodes in a laboratory at Rice University in Houston, Texas was illuminated for six hours to spell out the name of the institution in capital letters – RICE. That might seem unexceptional were it not for the fact that the 40mA of current at 2.4V that powered the display was provided by a set of bathroom tiles.

To be precise, it was provided by a lithium-ion battery charged up by a mix of mains current and a small solar panel that – and this is where the situation really was innovative and unusual – had been painted on to the surface of the tiles and which was just 0.5mm in depth.

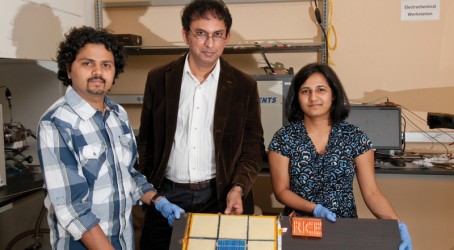

The exercise formed part of an 18-month project at the university that aimed to investigate a potential method of satisfying the increasingly urgent demand for appropriately slight batteries to power the increasingly lighter and thinner mobile devices, most obviously phones and computers, that consumer electronics companies are bringing to market. It is a demand confirmed by Neelam Singh: “There is now a lot of interest in unconventional battery designs,” she says. Singh is a graduate student at the university, who led the project as part of her work towards gaining a PhD. She says that, although the technique has only been demonstrated at laboratory scale, the project has proven that the concept is quite practicable.

Singh explains that the project, which got under way early last year, focused from the start on creating a paintable lithium-ion battery because that is the formulation “with the highest energy density of any battery technology,” an obvious priority if it was to be exceptionally thin. The research team – Singh mentions her tutor Professor Pulickel Ajayan and Charudatta Galande, co-author of the resultant paper, although others were also involved – came up with a composition involving five layers. These were in sequence:

- the positive current collector – carbon nanotubes and carbon black particles in N-methylpyrrolidone

- the cathode – lithium cobalt oxide, carbon and ultrafine graphite powder (UFG) in a binder solution

- a separator layer – Kynar Flex resin, PMMA polymer and silicon dioxide dispersed in a solvent

- the anode – lithium titanium oxide and UFG in a binder

- the negative current collector – conductive copper paint diluted with ethanol.

In each instance, says Singh, the team faced the challenge of achieving the required electrical and mechanical performance, which in the latter case meant ensuring that each layer of material would adhere to those next to it. But she says that the task was particularly acute for the separator layer that forms the core of the battery, not least because it had to be infused with electrolyte. Ensuring the adhesion of the separator was a “critical” factor, she says, because of the absolute requirement to avoid short-circuiting between the anode and cathode.

The team managed to create working batteries in which the materials were applied to a diverse range of surfaces, including a beer stein as well as the bathroom tiles. The tiles were the most complex of the power sources they achieved. Nine tiles were wired together in parallel, with one of them also carrying the solar cell. Not only did the battery work as a power source, it also proved capable of going through as many as 60 charging and discharging cycles with only a small drop in capacity.

Singh is confident that the achievement could have significant potential. She points out that painting is an established industrial practice and that upscaling the application procedure used in the project – a handheld spray gun – should be easy. The consistency of layer thickness achievable through an automated procedure should also, she adds, help to improve battery performance.

But infusion of the electrolyte at large scale might be trickier. It would probably require the development of a material that was not sensitive to oxygen or moisture and would not therefore require the process to occur in a controlled environment.

If those things can be got right, Singh foresees the prospect of batteries that could be painted on to almost any surface, regardless of scale. When combined with a suitable charging source such as solar panels, it could open up radical new prospects for the safe and clean generation, storage and delivery of electricity.

Meanwhile, on this side of the Atlantic, a small start-up company formed less than a year ago has already come to the market with a product which uses existing techniques to provide an innovative back-up power source for mobile devices. The company is Crosskase, based in Pease Pottage in West Sussex. The product in question is one of a range of backpacks designed to carry devices such as laptop computers.

But this one in particular – the Solar – incorporates a small solar panel which in any conditions of ambient light will continuously charge up a lightweight battery unobtrusively located in the backpack. The battery can then be used to recharge an electronic device so that the user can enjoy extended periods away from a mains source without running out of power.

The origins of the product are explained by sales director Matt Thorpe. He says that he and two friends came up with the idea after their mobile phones ran out of power at a music festival. None of them has a background in product design – Thorpe worked at the time in e-sales, although one of his colleagues had a degree in mechanical engineering – nor did they seek help from a design consultancy.

Instead they put in several thousand pounds of their own money and most of their free time in the evenings and at weekends to develop the concept. Thorpe says they then found a manufacturer in China through the made-in-china internet portal.

The product they have come up with looks like a conventional small rucksack except for what appears to be a clear plastic panel on the exterior. This is in fact a polycrystalline solar panel connected to a compact battery just 9mm thick and 80g in weight located inside the pack.

The battery can, says Thorpe, be charged up from empty by the panel in about eight hours in direct sunlight, although mains electricity and USB options from a computer are also available. It stores enough charge to replenish a typical mobile phone or similar small electronic device twice. The bag also comes equipped with a set of connectors to enable it to charge devices from a range of mainstream manufacturers including Nokia, Samsung, LG, Motorola, Nintendo and Sony Ericsson. It went on to the market in April at a retail price of £139.99.

The utility of the concept obviously stretches beyond that of text-mad teenagers never losing their ability to send a quick message. As Thorpe points out, it could just as easily provide back-up for a hiker out in rough terrain or be incorporated into a briefcase for business use.

He and his colleagues are already working towards further developments. A much more powerful battery capable of recharging a laptop computer is on the agenda.

And, much more futuristically, the notion of using more exotic means of charging up the battery is being mooted – possibly by using photosynthetic material over the whole exterior of the bag.

It all comes down to one unavoidable conclusion. However sophisticated mobile devices become, they still need electric power, so the once prosaic area of battery technology must continue to develop in similarly clever ways that ensure that requirement is satisfied wherever the user happens to be.