Engineering news

A huge variety of parts and disciplines are required to achieve similar dexterity, and very few efforts have come close to reaching it. Issues for anthropomorphic devices include the difficulty of fine touch, flexibility and prohibitively high costs.

Faced with those issues, researchers at the Southwest University of Science and Technology and Tsinghua University in China looked elsewhere in nature. Instead of humans, they hoped sea anemones could show a path forwards for gripping robots.

Sea anemones can capture creatures of different shapes and sizes thanks to their ‘doughnut’ shape. The Chinese team replicated it in a robotic gripping mechanism with a ‘bionic torus’, which captures and releases objects by crimping its skin.

A thermoplastic rubber skin lines the exterior of liquid-filled rings, and rolls inward when the inner skin of the gripper is pulled, sucking in a target. Researchers said they can adjust various features of the torus, such as rolling direction and length of the skin, to control whether items are engulfed, swallowed or released.

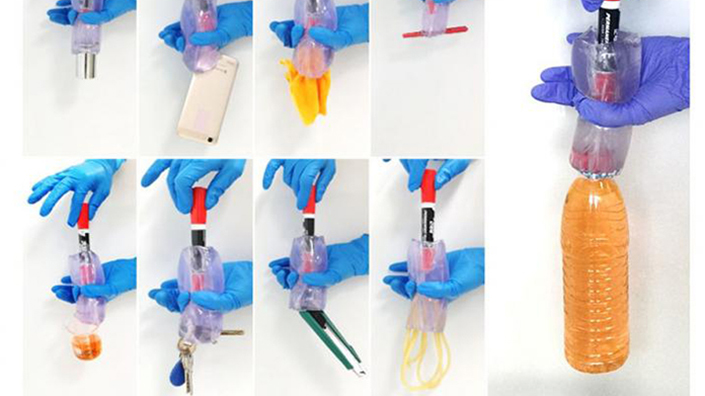

The grasper is reportedly relatively cheap and easy to produce, and it can grab a variety of objects of different sizes, shapes, weights and materials. The group demonstrated the device by latching onto a range of objects, including a piece of cloth, a mobile phone and a glass beaker filled with liquid.

The device successfully picked up a wide variety of objects (Credit: Weifeng Yuan)

Author Weifeng Yuan said flexible grippers could grasp fragile objects in narrow spaces or extreme, high-pressure environments, such as collecting samples of deep-sea organisms or operating in narrow pipes. The team said the device could also be built on a nanoscale to manipulate individual cells. The design has potential in the development of surgical instruments, said Yuan.

“Our grasper can grasp a steel bar from a table one minute and an egg from a basket the next without resetting control parameters,” he said.

The group will continue to develop the device and hope to increase the strength-to-weight ratio by using air instead of liquids.

The work was published in Applied Physics Letters.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.