Articles

By maximising recycling, carbon emissions can be cut and costs can be driven out of the business. Managed correctly, waste can even make money. Improving segregation on-site, ensuring materials can be recycled, and a good waste management partner will ensure you receive the best-possible value for your waste materials, with rebates directly contributing to your bottom line.

Effective waste prevention and innovative management can increase recycling, reduce energy use, cut emissions, and contribute to an overall healthier planet.

1. Review your waste

An independent waste audit can help identify where waste production could be eliminated or minimised. When did you last look in your bins?

2. Focus on elimination

Follow waste hierarchy principles throughout the production process. Can this process be improved and the waste reduced or minimised?

3. Be segregation savvy

Colour-coding, clear signage and graphics all help to ensure the right waste type ends up in the right bin. This has a knock-on effect to how much waste you’re able to recycle, and can even reduce the costs of disposal.

4. Staff engagement

One person can make a difference, but you can’t do it all alone. Engaging your team is imperative to success; take them on your waste journey.

5. Re-engineer processes

Waste production is inevitable. For waste that is produced, review how it’s being moved around your site by calculating waste ‘foot miles’. Is waste being double handled? Could it be managed and processed more efficiently?

6. Final destination

Reducing waste miles can have a direct effect on your carbon footprint. How far does your waste travel to its final destination? Is there another local option?

7. Reporting – You can’t change what you don’t measure

As with any department, it’s vital to report on the ins and outs of waste streams to ensure continuous improvement. Manufacturers now rightly expect regular reports, offering a bespoke look at costs, volumes of waste or recycling and how it sits against KPIs, carbon targets and more…

8. Mindful purchasing

Work with your procurement colleagues to assess the raw material you buy. Is there a more sustainable product available? Can packaging be recycled or even reused? By making better choices on raw materials, we can reduce the waste produced. Increased purchase costs can often be recovered through better waste disposal solutions.

9. Outsource waste

It’s essential to view waste as an essential part of facilities management and see it through the same lens as operations such as cleaning and security, which are typically outsourced to expert companies to ensure the best results. Waste can make you money and contribute to the bottom line, yet it’s rarely seen as a revenue stream. It’s vital that it’s handled and disposed of by specialists to ensure maximum rebate values, as well as maintaining housekeeping standard and compliance to avoid unnecessary safety or environmental risks.

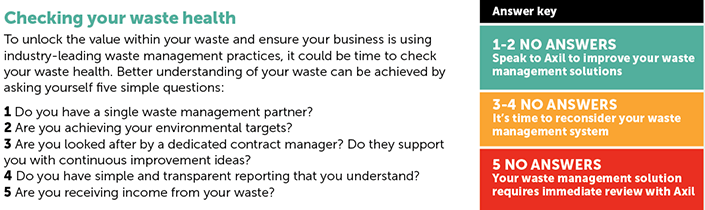

Challenge Axil to re-engineer costs out of your business waste. Arrange a free, no-obligation waste audit at axil-is.com

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.