A worldwide requirement for new energy sources means that unconventional technologies first trialled long ago are now being resurrected with a renewed sense of vigour and expectation.

That is certainly the case for underground coal gasification, a highly promising but undoubtedly controversial method of burning coal in-situ, typically several hundred metres beneath the surface, to produce a synthetic gas that can be used to produce electricity and for other industrial purposes. Underground coal gasification has been touted for decades as a viable means of deriving energy from the billions of tonnes of unspent coal reserves around the world. But only now are there serious efforts to prove the technology on a truly commercial scale.

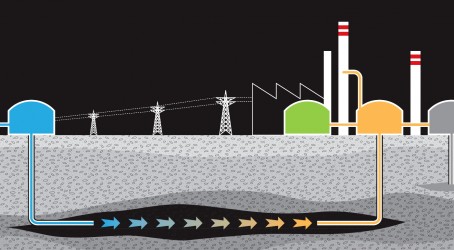

The extraction process is initiated by drilling a minimum of two boreholes into the coal reserves. A pressurised oxidant is injected into the first borehole and ignited in the coal seam. The resulting chemical reactions within the seam convert the coal into a combination of gases made up of hydrogen, methane, carbon dioxide and carbon monoxide, referred to as syngas. This is extracted through a second borehole and collected at the surface where it is treated to remove residual contaminants.

Syngas has a number of commercial applications including feed for power generation plants and iron and steel blast furnaces, gas-to-liquids processes and fertiliser/methanol production. The proponents of gasification claim that the technique offers many benefits compared with traditional extraction methods, most notably lower emissions as no coal is brought to the surface and the syngas can be processed to remove its carbon dioxide content. In addition, the CO2 produced could theoretically besold for enhanced oil recovery on mature oilfields. It could beinjected into the oil-bearing stratum at high pressure to increasethe amount of crude oil extracted.

But the technology is not without its detractors. For some, the thought of burning huge swathes of coal seams deep beneath the ground is one that provokes deep concern, both in terms of seismic and environmental impact. Indeed, an underground coal gasification trial at Kingaroy in Queensland, Australia was halted last year when traces of the chemical benzene were found in groundwater-monitoring boreholes. The Kingaroy incident has put underground coal gasification companies under the spotlight and proves the need for the highest standards of environmental disclosure. It seems that any shift to full commercial operation is unlikely to happen without an element of controversy.

International efforts

The technology itself has been researched and practised on a limited scale for many years. One underground coal gasification facility in Uzbekistan has been supplying syngas to a power station for more than 40 years, while a number of projects in Australia and South Africa have been operating on an experimental basis. There has been UK involvement too, most notably on a pan-European underground coal gasification field trial that operated in Spain for several years during the 1990s.

Despite these sporadic examples, efforts to progress the technology have been tortuously slow, mainly owing to the historical cheapness of natural gas, making it hard to establish a sound economic case. But as natural gas prices climb, and countries around the world look to establish an increased diversity of energy supply, there has been a resurgence of interest in the technology, with decarbonised underground coal gasification schemes having the potential to be used as a supplement to or substitute for natural gas.

“There is more activity around underground coal gasification now than there has ever been before,” says Kenneth Fergusson, a trustee of the UCG Association, the representative body for the industry. “Coal is an abundant natural resource, widely distributed, and it is far more prevalent than crude oil. If we can tap into that resource using methods that have less of an impact on the environment than traditional mining techniques, then underground coal gasification could have a big role to play in future energy provision.

“There are numerous trial projects being carried out around the world, and I believe that the first commercial example of the technology won’t be long in coming.”

Cheap green energy

In recent years, Australia has been the location for the greatest amount of underground coal gasification activity. At the forefront is Carbon Energy, which has built a pilot-scale 5MW power plant at Bloodwood Creek in Queensland and hopes to start selling electricity to the local grid later this year. A second-phase development at Bloodwood Creek will see the construction of an additional 25MW power plant. The larger facility is expected to incorporate carbon capture. Engineers at Carbon Energy are assessing what carbon capture technology is most suitable for the site.

Technical director Cliff Mallett says that progress at Bloodwood Creek represents the culmination of many years of research and development, a process that identified the site as being perfectly suited for underground coal gasification. “We have spent five years ticking off a thorough checklist of good operation, looking at technical aspects such as the coal cavity size and geo-mechanical and hydrological characteristics, and working out the most effective methods of pollution monitoring,” says Mallett. “It was a methodical approach that means we are confident that Bloodwood Creek offers an attractive proposition for cheap, green energy. Now we are going about proving that our modelling is correct.”

In terms of geology, Mallett says that the Bloodwood Creek site is particularly suitable for underground coal gasification because it has large resources of coals in decent-sized blocks measuring around 3 x 4km and up to 15m in thickness. The 5MW pilot site, which has been in operation since 2010, uses the syngas produced to power four engines. Mallett says that the trial has demonstrated that the coal gasification technology allows the production process to accurately control the chemical composition of the syngas.

“The design and operation of the gasification system has been proved to work beautifully,” says Mallett. “There is a lot of mechanical plumbing that surrounds all the required components and we have had issues such as blocked pipes and water accumulations in some areas. But it has all been relatively simple to fix. In terms of the process, we have seen nothing to say that it is not highly efficient, as predicted. It’s producing really good syngas.”

A scoping study is being undertaken for the additional 25MW power plant to be located at Bloodwood Creek. Ultimately the company plans to upgrade to produce about 300MW, but Mallett says this will only be achieved with additional financial backing. “There is real momentum behind what we are doing because the environmental advantages are clear.

“Around 70-80% of the energy from the coal can be exploited to produce the syngas. The process minimises surface disturbance by extracting the energy through a series of boreholes rather than mechanical excavation used in conventional mining methods. It protects groundwater reserves by operating the gasification process below the hydrostatic pressure and not pumping groundwater to the surface. Maintaining the surrounding groundwater pressure acts as containment for the gasification process and ensures that syngas flows to the surface under pressure via the production well. It also leaves rock and ash, originally mixed with the coal, underground in the coal seam.”

Carbon Energy isn’t the only company investing heavily in underground coal gasification. Another Australian outfit, Clean Global Energy (CGE), is also progressing several projects, particularly in the US. The main thrust of its activity is on a site in Oklahoma that is thought to comprise at least 20 million tonnes of coal, with an option to acquire adjoining mining resource containing up to 30 million tonnes. The site is located 13 miles from an existing power station which CGE plans to supply with the syngas that it produces.

Due diligence covering coal geological data, hydrology and infrastructure has been carried out and CGE suggests that the project will produce syngas for 25MW of electrical power production, with an option to expand and supply up to 300MW in a new, dedicated combined-cycle gas turbine at the nearby power station. CGE says that it has the funds in place to carry out initial drilling and upon finalising gasification studies it will seek further capital.

“We have identified the ideal coal tenement and the power station wants to take the syngas we produce,” says Michael Green, technical director of CGE.

“The two are separated by about 13 miles so it all adds up. We are about to start the drilling programme and that will evaluate the coal and give us samples and, critically, it will enable us to assess the hydro-geology. We have to get the hydro-geology right – that’s one of our main drivers.”

Clean Global Energy proposes to use Crip technology, using a single horizontal pipe to connect the injection and production wells, an approach that it says provides more control over where the gasification process takes place. This method is combined with directional in-seam drilling and generally uses oxygen or enriched air for gasification. Strict control of gasification chamber growth and movement, and keeping the position of the ignition point relatively close to the fresh coal seam, result in a uniform syngas composition, says CGE.

The process involves the drilling of two wells into the coal seam up to 600m apart. These wells are connected via a controlled retractable injection pipe. The gasification is started, with the coal ignited and combustion maintained by injecting air or oxygen and/or steam through the injection well. The gasification is controlled through the Crip mechanism, which moves along the coal seam from the production well to the injection well. The cavity is pressurised to contain the syngas produced, and the gas is extracted through the production well for clean-up and downstream processing.

Critical step

“The engineering challenge is that we are going to use one production well and several injection wells,” says Green. “Up to now we have done one injection well and one production well, but we’ve got to scale up to test this can work with two or three, or maybe even four injection wells, all providing one production well. That’s the critical step. The challenge is around issues such as pressure balances, avoiding back-flow and ensuring that all these systems work together and don’t have any adverse effect on each other.

“If you over-pressurise one injection well, it’s going to affect the others. The trick is getting the process right. We will be doing that in our proving tests before we go commercial.”

The ongoing projects in Australia and the US are proof that underground coal gasification has global appeal. However, in the UK progress has been laboured. Despite the Department of Trade and Industry funding research into the technology back in the 1990s, including advanced drilling techniques, environmental assessment and permit requirements, no underground coal gasification trial has ever taken place in the UK. However, a large number of potentially suitable sites, many located short distances offshore, were identified and many of these are now attracting interest from companies looking to exploit them.

For example, the Coal Authority has granted five offshore conditional underground coal gasification licences to Clean Coal, a London-based energy company. The licence areas are at offshore sites in Swansea Bay, off Humberside, in the Solway Firth near Canonbie, near Sunderland and off East Anglia. Their combined coal resource is more than two billion tonnes. Clean Coal is carrying out desk studies for these projects to assess their feasibility and viability. After the desk studies, Clean Coal says it will undertake exploration phases to confirm the suitability of the coal prior to planning the road to commercialisation.

The Canonbie project is thought to offer the greatest potential. The site is located on the northern limb of a major geological feature known as the Solway syncline. A seismic survey has provided evidence to support the presence of coal beneath the Solway Firth, but additional exploration drilling will be required to confirm the presence of thick seams suitable for underground coal gasification.

Clean Coal reckons that the area of the site is around 41km2, with minimum expected coal reserves of 103Mt, at a depth of more than 1,000m. The offshore location is deemed by Clean Coal as being advantageous, as an onshore site would be far more likely to run into planning objections.

Other companies are also being formed to capitalise on the potential offered by underground coal gasification. Newcastle-based business Five-Quarter was established in June to exploit untapped coal reserves under the North Sea.

The company, formed as a spin-off from Newcastle University, has secured approval from the Coal Authority to tap into subsea reserves in a 400km2 area, stretching from the mouth of the Tyne up to Alnmouth. Five-Quarter is now looking at a flotation or private-equity investment or a combination of both to raise the capital required to enable it to move forward with its ambitious plans.

Wildhorse gallops ahead

The first example of truly commercial underground coal gasification in the world is likely to take place in Hungary, where Wildhorse Energy is progressing a project in the Mecsek Hills that will see syngas used as a feedstock for power stations.

The project is being developed in two stages, with total output of more than 400MW being targeted. Economic analysis of the project has predicted coal consumption of 780,000 tonnes per annum over a 25-year lifespan. Wildhorse is currently in the process of selecting a site for its drilling and 3D seismic programmes, before it puts forward a definitive economic case. All being well, the project could be up and running in 2013.

The project sits right next to a power station run by Dalkia Energia, owned by French utility giants Veolia and EDF. Wildhorse has a memorandum of understanding with Dalkia that will see the utility firm buy the gas once pumping begins.

Matt Swinney, Wildhorse Energy’s managing director, says that early indications confirm the strong economic potential of the project and the value of underground coal gasification-derived syngas as a feedstock for power stations.

Many central European power stations now run on gas, and Wildhorse believes that if it can prove that underground coal gasification can reliably produce commercial volumes of syngas on the Mecsek project, other opportunities will open up in countries such as Poland, the Czech Republic and Germany.

“The results of our analysis indicate the potential role for underground coal gasification within the wider European unconventional gas market where there is an abundance of stranded coal,” adds Swinney. “Our strategy is to demonstrate the technology on a commercial scale at Mecsek Hills and then apply it in other European locations.”

Trouble down under

Opponents of underground coal gasification claim that the very act of burning coal in-situ is an extremely risky procedure that presents a host of environmental concerns, most notably that such activity could contaminate surrounding groundwater supplies.

Indeed, the shutdown of a trial plant in Kingaroy, Queensland, has given succour to the technology’s detractors. The site, run by Cougar Energy, was suspended in July last year when traces of the chemical benzene were found in one sample from groundwater-monitoring boreholes. An extended monitoring programme in the area carried out by the Department of Environment and Resource Management (DERM) confirmed that no benzene contamination was detected outside the perimeter of the Cougar Energy site.

DERM laid charges against Cougar for allegedly breaching conditions of its environmental authority. The charges related to the rupture of a gas extraction well in the early stages of the trial, alleging that Cougar failed to properly install the well to a standard necessary to ensure compliance with its environmental authority. The charges also alleged that Cougar released contaminants to groundwater, and failed to notify DERM of the contamination as soon as reasonably possible.

In a ruling earlier this month, DERM said that Cougar had not been able to prove that it could begin its operations without an unacceptable risk of causing environmental harm and therefore upheld a proposal to stop Cougar recommencing the trial. DERM is now finalising an action that will bring an end to underground coal gasification at the site, although Cougar has the right to have the decision reviewed and appealed.

Other underground coal gasification companies maintain that Kingaroy was a poor choice of site for such a trial, being located close to prime farming land. The Kingaroy event means that the state of Queensland has put a hold on all new underground coal gasification sites, although existing facilities such as Bloodwood Creek have been granted permission to continue operation.

Contaminants contained

The Controlled Retracting Injection Point (Crip) technique is an advanced underground coal gasification production method that relies on long-reach and horizontal drilling technology borrowed from the oil and gas industry.

The Crip itself is a movable tube through which oxidants, generally enriched air or oxygen and steam, are passed. This tube is inserted in a borehole drilled along the coal seam. So coal at any position along the seam can be exposed to gasification conditions, and the process can move along the seam in a fully controlled manner.

There are several variants of the Crip technique. In the US design, now also used in Australia, a second in-seam well is drilled alongside the Crip injection well and these come together around a purpose-designed ignition well.

In a method developed in Europe, meanwhile, deeper wells use an advanced form of Crip in which a vertical production well is drilled into the coal seam. Then the vertical section of the injection well is drilled to a predetermined depth, and completed with a special liner and an ignition source run into the well on coiled tubing. Directional drilling is used to bore often hundreds of metres through the coal seam until the production well is intersected.

Oxygen and steam can then be injected and gasification can be started at a specific position in the horizontal section. The process creates a gasification chamber that typically may be in the order of 20m wide and 20m long, although this depends on seam thickness and operating conditions.

As the process continues, the chamber fills with rubble, ash and char. When the process reaches the roof of the coal seam, more of the barren overburden will be exposed, reducing the efficiency of the process.

At a certain point, when the chamber is exhausted, the gasification process is temporarily suspended and the injection point retracted back along the coal seam, for about 30m (depending on the coal depth and thickness, which defines the size of the gasification chamber). The gasification process is then restarted.

Between 10 and 20 such retraction manoeuvres, perhaps more under ideal conditions, are expected during the lifetime of the gasification channel.

The exacting conditions that Crip provides bring an important environmental benefit, namely the ability to control underground pressure in the cavity, thereby ensuring that any contaminants produced during gasification are retained in the cavity region and do not spread to adjacent strata.