Prof. Meiling Zhu’s Energy Harvesting Research Group at the University of Exeter has collaborated with Babcock international Group to design and develop a whole vibration energy harvesting sensor system technology. The system the group has developed can deliver the equivalent energy to 100 AA batteries per year, adaptively suit for unpredictable and variable energy harvesting environments, and power data-rich, industrial wireless sensors.

In recent years the critical asset management and maintenance industry as a whole has increasingly adopted and deployed advanced monitoring systems using wireless sensor nodes in networks. However, the rollout of increasingly widespread and large-scale wireless sensor nodes has been severely restricted by the issue of power supply. Currently, most digitalised monitoring systems are powered by either batteries or wired connections to mains. However, as the Industrial Internet of Things (IIoT) develops and the need for advanced digital monitoring of equipment increases, these traditional approaches using batteries and connecting to mains as electrical power sources become unsustainable and impractical. Various industries have genuine concerns regarding space constraints and the complexities of wire routing, particularly for the sensors deployed in restricted spaces and with no or limited access to fit-hard-wired solutions. Battery life, changing and charging batteries, and the maintenance and management costs for large scale IIoT connectivity present significant challenges. With the evolution and expansion of the IIoT, relying on batteries and running wires will no longer be a viable option for critical asset health monitoring.

One powerful means of sustainable and practical power supply is to develop energy harvesting technologies, which capture energy from the surrounding environment via a harvester, convert, and store it into usable electric power via a power management circuit, enabling wireless sensor nodes to be operated in an energy-autonomous manner.

What capability of the vibration energy harvesting sensor system has the group has developed?

Prof. Meiling Zhu’s Energy Harvesting Research Group at the University of Exeter has collaborated with Babcock international Group to design and develop such a system. The group has constructed a deployable vibration energy harvesting system capable of delivering sufficient usable energy to power wireless sensor nodes and supporting advanced data-rich telemetry. The system provides self-power digitalisation capability to industry standards without the need for changing or charging batteries. The group’s system comprises three core technologies: a piezoelectric energy harvester, an efficient and adaptable power management circuit, and a low power wireless sensor node. When mounted onto machinery or other industrial plant equipment, the system harvests vibration energy from these structures and converts it into the power supply for wireless sensor nodes. The sensor nodes measure key asset health- and safety-related parameters such as vibration, temperature and loading conditions, perform a local FFT analysis (edge computing) and wirelessly transmit the measured and analysed data to a gateway. The system has many unique characteristics and features. Some of them are listed below.

Sufficient Usable Power: the system can harvest 15-140 mW at 0.1-0.5g of vibration and have high reliability in real-world applications. A look at the power harvested suggests it was a huge success for the group. “We are ecstatic; this is the highest power ever harvested at a typical range of real-world vibrations of 0.05-0.5g. The higher the power harvested at the typical range of industrial vibration, the more usable the technology is. There aren’t any adjectives that could describe how widely our energy harvesting system can be used to service many industrial sectors, such as high-value machine and critical industrial plant equipment or asset of condition monitoring for predictive and preventative maintenance”, says Prof. Zhu. Prof Zhu added: “Our research at Exeter is all about developing truly deployable energy harvesting technologies and systems for self-powering sensors to power IIoT, and deliver sustainable industrial digitalisation into the 21st Century”.

Adaptive and Efficient power management: the power generated from the vibration energy harvester is further optimised by innovative electrical and electronic circuits utilising energy-efficient self-configuring methods. These enable adaptive and efficient maximum energy delivery from the harvesters to the wireless sensor nodes under real-world operating conditions. “This flexibility means the system can operate over a wide range of vibration levels, removing the need to redesign the circuit to optimise performance on a case by case basis”, says Prof. Zhu. More importantly, the technology incorporates an energy-aware approach, enabling wireless sensor nodes to adapt to unpredictable and variable energy harvesting environments, operating efficiently and reliably, regardless of the energy mismatch between that generated by the harvesters and demanded by the wireless sensor systems. As Prof. Zhu explains, the Energy Harvesting Research Group’s multi-disciplinary approach is really critical when designing and implementing end to end solutions.

Data-rich sensing, local FFT analysing and wireless transmission: The system can continuously measure sensor signals at a sampling frequency of up to a few tens of kHz, perform a local FFT signal analysis, and transmits many data and points when the vibration is larger than 0.20g, satisfying highly dynamic vibrational signal measurement for frequency-domain analysis. “Our local FFT analysis allows to turn the vast amount of data from the node measurement into useful information and let end-users know what will happen in the frequency domain. This is especially true if you want to make a useful prediction”, Prof. Zhu said.

Although many other research groups have developed vibration energy harvesting powered wireless sensor nodes, the Exeter Group’s system is more powerful, truly deployable, delivering sufficient usable power in duty-cycle (sometimes on and sometimes off) mode even when the vibration is very low at 0.05g-0.1g and can power wireless sensor nodes.

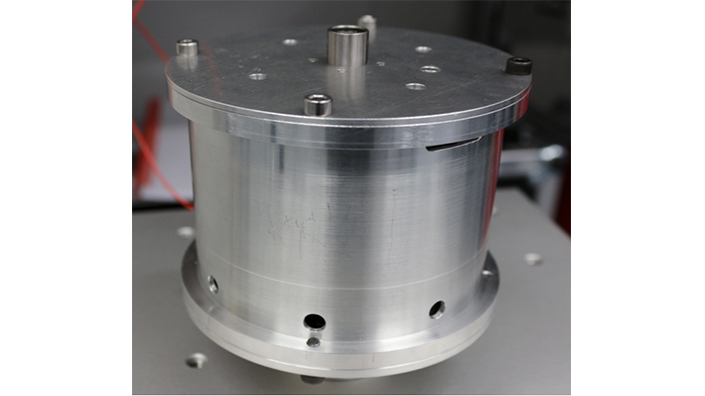

The manufactured energy harvesting sensor systems

How many AA batteries of energy can the system produce during one year of operation?

The group has compared the energy harvesting capability they have developed with standard AA batteries to confirm how effectively the system could replace batteries when operated without charging or changing batteries. For example, AA batteries typically have a capacity of 2500mAh; the group’s system harvests an average power of about 15mW at 0.125g, and 43 mW at 0.25g at an industrial site of air compressors. Prof. Zhu added: “these vibration levels typically exist in many other industrial machines and plants. The high power harvested is critical for industrial applications. This means that our system just needs to spend 250 and 87 hours harvesting vibration at the levels stated above, to generate the equivalent energy that one fully charged AA battery has”. When continuously harvesting at 0.125g and 0.25g of vibration in the industrial site, the system produced energy, equivalent to 35 and 100 standard AA batteries, respectively, during one year of operation.

How many AA batteries can the system save when powering data-rich wireless sensor nodes?

What’s more, the group has studied the power consumption of a wireless sensor node they have developed to confirm further how many battery replacements can be saved in a year when using their system. For example, the node using a wireless protocol of Sub-1GHz and a power-hungry accelerometer consumes 27.6 mJ for 1.38 seconds, sampling 2048 point with 2048 Hz sample frequency, performing a local signal FFT operation, and transmitting 2048 sampled data and FFT results. This means the system would need 24 and 5 replacements of 2 AA batteries (usually 2 AA batteries per wireless sensor nodes) in a year for continuous and 20% time active operation, respectively when batteries would power the system.

What key benefits can the system bring to wireless sensors?

A look back at the number of the equivalent standard AA battery energy harvested during one year of operation shows the energy harvesting powered a wireless sensor node they have developed is truly capable for industrial dynamic monitoring applications. Prof. Zhu said: “our system is capable of data-rich sensing, FFT analysing, and wireless transmission for advanced industry monitoring applications”. Prof. Zhu added: “our system enables wireless sensor nodes to operate for years without the need for batteries, eradicating concerns related to energy deterioration affecting sensor node operation. Once installed, it can be a fit-and-forget solution to gather, analyse and transmit data, and no battery maintenance costs, including the time and workforce required to check and replace batteries. We are very excited by this technology we have developed; our system can completely replace batteries in wireless sensor networks, so you don’t need to worry about batteries going flat any more”.

What is the current technology level of the research and development?

This whole system has been successfully demonstrated under emulated real world conditions in the Energy Harvesting Research Group’s lab, and the energy harvester that is one part of the entire system has been tested at TRL level 7 by engineers at Babcock’s Devonport Royal Dockyard. The whole system will be installed to conduct real-world testing for critical air compressor monitoring as soon as site COVID restrictions allow. Prof. Jim Sibson, Babcock International Group’s Head of Research and Partnerships, said: “We are delighted to be able to offer a real world proving ground for this cutting edge technology. The opportunities that this technology presents are very exciting for industry, the performance of this system is outstanding, the energy harvested means that the wireless sensor nodes can comfortably meet our asset monitoring needs, allowing us to place sensors in remote or difficult to access areas. Furthermore, the self-configuring capability of the circuit means it can be easily applied to the range of different equipment that we support without the need to conduct expensive engineering studies and redesign activity.”

What is the next step for the research and development?

The next logical step to pursue is to develop a commercially deployable technology demonstrator to a pre-production built standard capable of undergoing assessment for regulatory approval. Prof. Zhu’s Group has filed a patent and plans to bring the energy harvesting technology to market via a spin-out company which will be launched later in 2021. Meanwhile, Prof. Zhu’s group will research scalable, low cost, high-performance energy harvesting systems for large scale industrial monitoring applications. If you are interested in learning more about the technology or the work of the Energy Harvesting Research Group, please contact Prof. Meiling Zhu (m.zhu@exeter.ac.uk).

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.